oestex.com©

OPTIMISED ULTRA-LINEAR ©

HI-FIDELITY

AUDIO AMPLIFIERS

* * *

In 1936, Alan Blumlein was granted UK Patent 496883 covering a design concept describing a particular form of loading configuration for power tetrodes, pentodes and beam power tubes in electron tube amplifiers whereby the Screen Grids (Grid 2) are fed from a tapping in the primary Plate winding, or from a separate discrete Screen-Grid winding, of the output transformer.

Later, writing in the November 1951 edition of the US "Audio Engineering" magazine, David Hafler and Herbert Keroes of the Acro Products Company, USA, used the term "ULTRA-LINEAR" to describe a specific form of this mode of operation.

This paper explains the positive benefits of ultra-linear operation and its

superior performance to conventional tetrode, pentode or beam power tube

designs. It also describes the OPTIMISED

ULTRA-LINEAR © concept.

"ULTRA-LINEAR" operation is also known as "DISTRIBUTED-LOAD" operation - because the Screen-Grid is driving into a determined load impedance, which also delivers power output through the output transformer.

"Ultra-linear" distributed loading may be used for either single-ended or push-pull configurations.

"Ultra-linear" distributed loading may also be used for driver stage voltage amplifying tubes. In this case the transformer is replaced with a system of resistors and capacitors to produce the same load sharing and negative feedback result.

The basic push-pull ultra-linear power output stage design looks like this:

The Screen-Grid tapping may be at any point between 0% (Pentode Connection) and 100% turns (Triode Connection) - typically within the range 40 to 43% turns or 16 to 18.5% impedance for best effect - when measured from the centre-tap to each Plate.

The basic ultra-linear configuration as shown above therefore avoids the need for a separate Screen-Grid supply, thereby offering improved performance at no real extra cost. In fact, it enables total elimination of the independent "regulated screen supply" seen in professional quality tetrode, pentode or beam power tube amplifiers, resulting in a real cost-reduction, space saving and improved reliability.

This feature is very significant to hi-fi audio because the necessity for a regulated Screen-Grid supply to attain high quality performance was widely acknowledged since the 1930's.

For comprehensive details of the traditional ultra-linear amplifier design and attributes see my ULTRA-LINEAR page - this page should be studied before proceeding further.

That page presents or references considerable theoretical analyses of the

ultra-linear methodology.

The Ultra-linear "Sound"

The sonic properties of the ultra-linear output stage configuration - albeit single-ended or push-pull design - are described by reviewers as being midway between triode and tetrode "tone".

Some audio-engineers describe the sound of triodes as "smooth, sweet, mellow, natural" and tetrode/beam power tubes as "clean, bright, sharp, punchy".

The ultra-linear configuration also offers improved overload characteristics, resulting in more effective power output - ie what the listener actually hears at full power levels.

Technically speaking, the ultra-linear configuration delivers the same power output as for pentode operation of the same tube under the same operating conditions and typically about twice the power output of triode operation of the same tube under the same operating conditions with the same applied DC voltages - but with substantially less harmonic distortion or intermodulation distortion (see comparative performance graph below).

Output impedance is similar to triodes, allowing minimal or zero negative

loop feedback to be used.

Ultra-linear Circuit Characteristics:

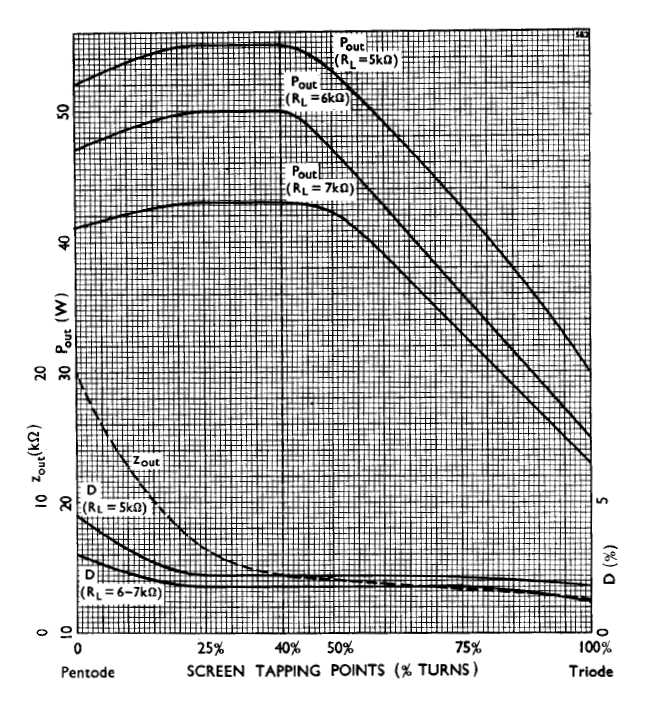

The following graph, courtesy of GEC and AWV Radiotronics Magazine (May 1959), shows the comparative characteristics of the KT88 beam power tube in triode, pentode and ultra-linear connections under specified load conditions.

These comparative relationships between the different connection configurations should be typical for most (but not all) tetrodes, pentodes and beam power tubes.

Note:

- the relationship between output impedance and ratio of

screen tap turns.

- the relationship between output power and ratio of

screen taps.

- the relationship between THD distortion and ratio of

screen taps.

- the effect of load impedance upon output power.

- the power output for the KT88 in ultra-linear operation

is greater than that for pentode (tetrode) or triode operation.

Hafler and Keroes, in their US Patent 2,710,312, demonstrate the performance

of their ultra-linear concept by the following graph:

Plot A shows the tube internal impedance for the various screen taps of 0% (tetrode connection) to 100% (triode connection). The result is expressed as "R" in the table. It can be seen that tetrode connection has a very high tube impedance and triode connection a very low tube impedance.

Plot B shows the "undistorted" power output in Watts for the amplifier used in their tests - expressed as "W" in the table.

Plot C shows the level of high-level intermodulation distortion for the amplifier used in their tests - expressed as a "percentage".

Important: Note the extremely high level of IM distortion for push-pull triode operation (more than 30%). This explains why commercial manufacturers of triode configured amplifiers (particularly those of the single-ended variety) rarely - if ever - reveal the intermodulation distortion performance.

Plot D shows the level of low-level intermodulation distortion for the amplifier used in their tests - expressed as a "percentage"

Negative loop feedback was not used in the test amplifier.

This graph clearly demonstrates that performance described as "ultra-linear" is available only under very specific operating conditions.

In all other cases, the term "distributed load operation" is more appropriate.

It is the "ultra" that makes all the difference.

This is proven by the GE "Operation Characteristics" graph below, that shows for a 6550 tube in push-pull ultra-linear mode, the load impedance can range from 2,000 Ohms plate to plate to 12,000 Ohms Plate to Plate for reasonably constant power output. This performance contrasts markedly with modern solid-state amplifiers that, as a class, suffer from dramatic power loss as the load increases - proportionately downwards - eg 100% at 2 Ohms, 50% at 4 Ohms and 25% at 8 Ohms etc.

This is why solid-state amplifiers generally

suffer from a lack of bass response when driving loudspeakers, whose impedance

may typically be around 100 Ohms at low frequency. A bass boost circuit becomes

essential to offset this effect for flat audible response. See also my "How To" page.

OUTPUT IMPEDANCE

Output Impedance is a very critical parameter for high-fidelity reproduction, particularly when no loop negative feedback is used from the loudspeaker circuit.

The above graphs show how Output Impedance is dramatically reduced by ultra-linear operation of the output stage.

Output Impedance can be further reduced on a pro-rata basis by the use of multiple pairs of output tubes.

The following article, courtesy of Amateur

Radio Valve Technique, published by The Radio Society of Great Britain

1948, explains what "Output Impedance" is, how it can be measured,

and its effect on performance.

LOAD CHARACTERISTICS

Triode, Tetrode and Pentode operation are generally critical as to load.

However the following graph, courtesy of GE USA (4/72 6550A data sheet), shows the excellent linearity of power output versus load impedance for the 6550 in ultra-linear connection.

It can be readily seen that Power Output and Harmonic Distortion are relatively independent to the load.

This is a most important feature when using loudspeakers, which are renown for presenting a varying load to the amplifier.

The above load curve demonstrates that markedly increased speaker impedance at resonant frequency will not produce a spike in power output as seen in conventional Tetrode or Pentode operation. This is a very worthy attribute for a hi-fi audio amplifier.

Note: It will be seen from the above graph that the best performance is realised with a load of about 9000 Ohms Plate to Plate. This is exactly twice the load recommended by GEC for the KT88 under similar conditions, suggesting the KT88 and 6550 tubes are not directly interchangeable when optimum performance is required.

It will also be seen from the GEC graph above that the KT88 behaves very

differently under load variation than the 6550.

Recent Research

I am indebted to Rudolf Moers, a distinguished Electrical and Electronics Engineer located in the Netherlands, who has made available for us his wonderful recent scientific investigation into the design theory and practice of Ultra-linear audio amplification.

These papers are posted with permission from Linear Audio www.linearaudio.net and their author Rudolf Moers.

Part 1 - Power Point presentation

Part 2 - Power Point presentation

Parts 1 and 2 combined presentation - pdf format

Paper - The Ultra-Linear Power Amplifier: An adventure between triode and pentode - pdf format

The engineering design methods developed by Mr Moers may be used to

determine theoretical plate/screen load ratios for

ultra-linear operation of power tubes.

The detailed work of Mr. Moers may contain some surprises for the

traditionalist.

Summary:

In summary, traditional ultra-linear connection offers:

- useable power output equal to or approaching that of

tetrodes and pentodes but with substantially reduced harmonic and

intermodulation distortion and improved tonal characteristics, thus making

it the preferred configuration for high-fidelity applications.

- a "warmth" of tone across the full audio

spectrum, not evident with the "clinically clean" sound of unity

coupling - where the load is distributed between plate and

cathode, or the "hardness" of tetrode or pentode configurations,

or the "muddiness" (but pleasant) of triode connected tetrodes

or pentodes

- simplicity in circuit design and construction

- elimination of need for a separate regulated power

supply to the screen-grids

- employment of a simple output transformer

- constant-voltage negative feedback

- high stability operation over a range of reactive and

capacitive loads.

- wide-range frequency response

- strong useable low-frequency power output - ie as heard

through the loudspeaker

- smoother overload characteristic than tetrodes,

pentodes or beam power tubes

- good dynamic range performance and transient response

- higher output stage to loudspeaker coupling efficiency,

resulting in a perception of "louder" reproduction

- ideal tube amplification for bass guitar amplifiers -

ie high power, low output impedance, freedom from bass resonance

Ultra-linear operation also enables lower

quality loudspeakers to be used for satisfactory results.

IMPORTANT: Performance described as "ultra-linear" is available only under very specific operating conditions - usually where the Screen load is 18.5% impedance or 43% turns of the Plate load impedance - measured from the power supply source terminal.

In all other cases, the term "distributed load operation" is more appropriate.

OPTIMISED ULTRA-LINEAR © HI-FI AUDIO AMPLIFIERS

© NOTICE: INTELLECTUAL PROPERTY COPYRIGHT D.R.GRIMWOOD 2002 - ALL RIGHTS RESERVED. NO PART OF THIS TECHNOLOGY MAY BE USED FOR COMMERCIAL PURPOSES IN ANY FORM WHATSOEVER INCLUDING BUT NOT LIMITED TO PRODUCT DEVELOPMENT OR GAIN OR REWARD WITHOUT THE EXPRESS WRITTEN PERMISSION OF THE AUTHOR.

On the available evidence, the "ultra-linear" concept appears to have been first introduced publically by David Hafler and Herbert Keroes of the Acro Products Company, USA in the November 1951 edition of "Audio Engineering" magazine.

This was an outstanding development for their new company, Acro Products, which they had founded only a year earlier in 1950.

In their "ultra-linear" concept US Patent Application in May 1952 (Serial Number 288,908) (Granted 2710312 - June 1955), Hafler and Keroes described the results of their obviously extensive practical research over the many years since the original 1937 pioneering work of Alan Blumlein - UK Patent 496883.

Hafler and Keroes concluded their "Statement of Claims" with the remarkable statement: "Whatever the true explanation, the plate transfer characteristics of the tetrode arranged in accordance with our invention are remarkably linear."

It is now evident from the documented record, that although patenting Screen-Grid tap impedance ratios of 0 to 100% (Blumlein) or 5 to 30% (Hafler and Keroes) of Plate load impedance, none of the aforementioned patents attempted to explain the theoretical basis for those claims beyond describing it as "a system of negative feedback". Notwithstanding the earlier work of Blumlein, the evidence presented by the inventors to support their patent claims was essentially empirical, supported by documented results of their extensive and thorough verifiable experiments.

The Patent itself, only focuses on two primary tube types - viz the 6L6 family (including 5881, 807 and KT66) and the 6V6 family, suggesting that in the urgency to file the Patent claim, Hafler and Keroes limited their work to the then popular audio tube types. However the Patent claims the invention is suitable to any "analogous" tube type.

Fate then intervened in the evolutionary process of "ultra-linear" amplifiers and history shows David Hafler left Acrosound in 1954 (which was the year before their joint patent was actually granted in the name of Acro Products Company) and joined with Ed Laurent to form the Dynaco company in 1955 - a company now famous for its manufacture of fine amplifiers.

It has been reported that by 1955, due to its ready acceptance by the hi-fi industry, the patented ultra-linear design - owned by Acro Products - was licensed to more than 20 major audio manufacturers, including Dynaco, Eico, Fisher, Harmon-Kardon, Marantz and Scott. Professional sound licensees included Altec-Lansing, Ampex and Fairchild - an incredible endorsement by big name brands.

Also in October 1955, a few months after the granting of Patent 288,908, Herbert Keroes lodged a further patent application for his state of the art design of a push-pull output transformer for ultra-linear applications (US Patent 2791646 granted May 1957). This design was a great leap forward for audio, being an incremental extension of his previous patents 2680218 (1950) and 2710312 (1952).

The novel features of his transformer design were sectionalised windings for primary and secondaries, multiple impedance secondary windings and a separate tertiary winding for the screen-grids to enable use of high-voltage, high-power tetrode, pentode and beam power transmitting power tubes in ultra-linear configurations.

Typical transmitting tubes have strict restrictions on the maximum applied DC Screen-Grid voltage, which is always significantly less than the Plate DC voltage. This new transformer design opened the way to use of high power output tube types not previously available to ultra-linear amplifier designers.

To promote the Acro Patent 288,908 ultra-linear transformer concept, a high-quality 100W ultra-linear amplifier design using this transformer (Acrosound TO-350) and 6146 VHF transmitting tubes was published in the Acrosound Catalogue of 1955. In this case the Plate voltage was 725 VDC and the Screen Grid voltage 220 VDC.

It should be noted that these same transformer attributes had already been covered for single-ended operation in the previous patents referenced above.

The Acrosound Ultra-linear Transformer Catalogue says:

Joseph Marshall, writing later in "Radio-Electronics" magazine, said:

It is apparent from studying the original patents of Alan Blumlein (1936) and Hafler and Keroes (1951) and other respected commentators, that none were quite clear on why the ultra-linear design does what it does.

Other highly acclaimed audio engineers, like Norman Crowhurst ("Audio"Magazine 1959), and even F. Langford-Smith (Radiotron Designers Handbook 4th Edition - 1952) also appear not to have understood precisely why it is so.

D.T.N. Williamson (MO Valve Co. UK) and P.J. Walker (Quad Audio), writing in the September 1952 edition of the Wireless World Magazine, described the Hafler and Keroes invention as "distributed load" operation and essentially rejected the claims made in the Acrosound Patent, declaring that both straight pentode operation and the Quad Cathode coupled design (as used in the Quad II Amplifier) are superior. They also described the concept solely in terms of a negative feedback system.

Of interest is the deliberate use of the descriptor "distributed load" by Williamson and Walker, indicating their distaste for the "ultra-linear" label.

There may have been some commercial bias in this presentation, however that was short-lived because their competitor Mullard Valves UK, in "World Series Audio" publications, introduced a series of designs for "distributed load" amplifiers using their EL34 and EL84 tubes. Importantly though, they did not expand on the "distributed load" concept, preferring to describe it in terms of a system of providing Plate voltage to Screen Grid feedback.

In their 1960's "Mullard EL34 World Series Valves" brochure, Mullard say: "An interesting method for operation of high-quality domestic amplifiers is to use two EL34's in a push-pull output stage with distributed load conditions. The Screen Grids are connected to taps on the primary of the output transformer, so that part of the primary load is common to the Anode and Screen Grid circuits." This publication did not provide limiting values for "distributed load" operation.

Later Mullard publications suggest they doggedly adhered to the "distributed load" term until the demise of the Mullard business some years later, without ever providing explanation of how it worked.

When the MO Valve Co/GEC introduced the KT88 in November 1956, they did not provide recommendations for use in distributed load amplifier applications at all - ie just triode and pentode applications.

But most importantly, from March 1959, MOV/GEC used the term "ultra-linear" for their KT88 data sheets and amplifier designs. Not only did they abandon their own Mr Williamson's "distributed load" concept, but they published data, test results and graphs to demonstrate that "ultra-linear" operation is superior to triode or pentode operation!!

Thus, as the KT88 became "the" tube to use for high powered ultra-linear audio amplifiers, the term "distributed load" became lost to posterity.

In November 1959, Norman Crowhurst, writing in "Audio" Magazine, described the advantages and disadvantages of "ultra-linear" operation, expressing his choice of terminology.

However RCA remained non-committed, describing this mode of operation in their January 1959 RC-19 and August 1964 RC-23 Receiving Tube Manuals for types 6973, 7027 and 7868 tubes as simply "Grid #2 of each tube connected to tap on Plate winding of output transformer, so as to supply 43/50% of the Plate signal voltage to Grid #2 of each output tube".

Neither Telefunken nor Philips (the parent company of Mullard UK), appear to have referred to the ultra-linear or distributed load concept at all in their tube handbooks or data sheets.

But in 1972, GE USA used the term "ultra-linear" in their 6550A data sheets. Full marks to GE, who at last did assign a maximum rating for this class of service.

But regardless of terminology, the profound words of Hafler and Keroes in 1952 - "Whatever the true explanation" - clearly convey a level of uncertainty in the theoretical principles that support their applied engineering design.

For his part, Herbert Keroes, the transformer guru of the team, did not add further ultra-linear designs to the Acrosound range and does not seem to have pursued the subject further. Since his original TO-350 amplifier was so good he may have felt it unnecessary to expend further effort on the concept. After all, the Acrosound Transformer Catalogue describes this 100W amplifier as delivering "high-fidelity power to fill a stadium". Certainly in that era, 100 watts was more than the average home audiophile would have interest in, with the then available loudspeaker systems being typically rated at 25 Watts RMS max. In a stereo application the home or cinema user would have 200W rms available from this amplifier, which in that era would have been overwhelming for most typical applications.

Ironically this development occurred at the same time users were moving away from the use of high-voltage "top cap" tubes - eg to 6L6 instead of 807 - and the outstanding possibilities from this development in transformer design were essentially wasted by consumer resistance. PA and guitar amplifier manufacturers introduced multiple parallel pairs of output tubes instead of single high voltage pairs, enabling the tertiary Screen-Grid winding to be deleted for lower cost.

The technology for transformers suitable for conventional tetrode, pentode and beam power tube amplifiers, including the Acrosound sectionalised winding design covered by US 2680218, was already well developed and documented.

These design specifications and descriptive literature clearly indicate the ultra-linear concept had by then been fully practically developed.

Acrosound may well have been satisfied with their sales revenues, licensing the design and/or supplying transformers to the bulk of the major hi-fi amplifier manufacturers at that time.

In the case of David Hafler, it appears that other than producing an ultra-linear version of the Williamson triode amplifier, and higher power conventional ultra-linear amplifiers, there is no record of Dynaco commercially exploiting the Ultra-linear concept further. One reason for this may have been Herbert Keroes' ultra-linear transformer patent 2791646 - application lodged October 1955, the same month that Dynaco was incorporated. This "Patent Pending" would have made it extremely difficult for other manufacturers to design a commercially competitive transformer. The actual patent was not granted until May 1957, effectively locking up the design for two years, then for a further 14 years during the patent period.

So the patent did its job well, stifling further development until after transistors had replaced tubes in the popular hi-fi market and the ultra-linear technology became displaced by technological progress.

David Hafler died May 25, 2003.

So the historical record suggests that from 1955, commercial competitive forces prevented further development of the ultra-linear concept.

Of historical interest is that the original "Cinerama" seven channel 120W rms cinema surround sound system introduced in 1955, whilst using 6146 tubes, did not use the ultra-linear concept, opting to stay with the tried and true pentode connection and regulated Screen-Grid supply. One reason may have been that the only tubes available at that time capable of delivering 120W rms were also transmitting tubes and the 6146 was a proven reliable performer - the KT88 had not yet appeared as an option.

One notable exception is the McIntosh MC3500 and MI-350 duo, introduced in 1968, which combines the Acro ultra-linear design concept with the McIntosh unity coupling configuration to produce an outstanding audio amplifier featuring unequalled performance.

Given all the above, it follows that in the search for "why is it so?" - or cause and effect relationships - the performance of an Ultra-Linear amplifier might be substantially improved by giving consideration to vacuum tube design, construction and behaviour - ie beyond thinking of the ultra-linear concept exclusively as a transformer technology or negative feedback system.

Research I have undertaken indicates that the conventional approach to the design of Ultra-Linear circuits has been limited not only by commercial forces, but also technological precedent and custom.

It is time to think outside the square. Time to rethink. Time for a new paradigm!!

Performance results have been less than ideal - there must be a better way.

The OPTIMISED ULTRA-LINEAR © concept demonstrates a better way.

Introduction to OPTIMISED ULTRA-LINEAR ©

History tells us that from the three choices of tetrode, triode or ultra-linear configuration, the latter was the preferred configuration for 1950's to 1960's hi-fi, because it offered the tonal "sound" of triodes, substantially lower distortion - particularly intermodulation distortion - with power approximating tetrodes, at a cost comparable with tetrodes.

Ultra-linear amplifier designs of that era provided commercially competitive high quality sound. In particular, ultra-linear amplifiers delivered excellent transient response from simple power supplies.

Ultra-linear amplifiers typically used cathode bias, which provides excellent reliability and extends tube life so, in addition to their sonic qualities, ultra-linear amplifiers also developed a reputation for long tube life and reliability.

Hence, by about 1960, the commercial development of Ultra-Linear design technology plateaued, simply because conventional Ultra-Linear technology having equal Anode and Screen-Grid voltages offered a significant improvement on full triode operation of tetrodes or pentodes at virtually no increase in total cost, and there was no real incentive to develop the concept further.

After publication of their 100W ultra-linear amplifier design using 6146 VHF transmitting tubes and the Acrosound TO-350 transformer about 1958, the published work of Hafler and Keroes of the Acro Products Company (Acrosound) appears to have exhausted further development possibilities from them.

It seems most commercial manufacturers of top-end audio amplifiers preferred the conventional ultra-linear configuration having equal applied DC voltage to Plates and Screen-Grids, which is clearly cheaper per watt of output power. That situation appears to have continued through to the present time.

From the outset, tubes like the KT88, KT90, EL34, EL84, 6973 and 6550 made it practicable for commercial amplifiers to be designed without an extra Screen-grid winding and without an extra regulated Screen-grid power supply. The availability from current manufacture of these proven tubes ensures continuation of this popular design.

This observation is also true of output stage configurations other than ultra-linear.

One exception was the great Bruce de Palma, who designed a series of hi-fidelity ultra-linear amplifiers using reduced Screen-Grid voltages - sufficient to ensure the Screen-Grid performed its proper function of attracting and regulating electron flow from Cathode to Anode, and to extending tube life - but not for the purposes described herein. His ideas found little support in mainstream commercial applications, presumably because of the extra cost and complexity of the output transformer and necessity for a separate and extra regulated power supply for the Screen-Grids.

In any event, despite the availability of the Acrosound T0-350 and its modern day retro-fit equivalents, no-one appears to have ever publically argued superior performance for ultra-linear amplifiers using a proportional voltage separate power supply to the Screen-Grids of receiving or transmitting tubes, and the concept has been lost to historical curiosity.

Also, what has not been fully appreciated is that when compared with true triodes, triode connection of tetrodes and pentodes offers only compromise performance because of the physical placement and operation of the Screen-Grid (Grid #2) and its effect upon overall performance - for details see my papers on Screen Grids and Triode Operation.

That is to say, even though triode connection of tetrodes and pentodes works in practice, and has been widely used for seventy or more years, it is not a technically ideal approach - because the Screen-Grid acts as a pseudo anode, and in so doing ADVERSELY changes the behaviour of the electron stream within the tube - particularly when the applied DC voltage to the Screen-grid exceeds the design maximum rating for tetrode/pentode operation - causing unstable operation and even loss of control over electron flow ("thermal runaway" or "dynatron" effect (RCA).

Similarly, in relation to Screen-Grid placement and function, the same

constraints and consequences apply to Ultra-Linear operation of tetrodes and

pentodes.

An Explanation.

First a look at the basic ultra-linear circuit.

The typical AC (alternating current) power tube output circuit looks like this:

For simplicity, the DC Direct Current power source is not shown and the Screen-tap is set at 43%. The capacitor is assumed to have zero impedance.

THREE output circuits are formed - the Cathode to Plate circuit, the Cathode to Screen circuit and the Screen to Plate circuit.

The Cathode to Screen circuit and the Screen to Plate circuit are in series both in the tube and in the transformer.

Each circuit is independently connected to its respective load - ie the transformer. This configuration is very different to pentode operation where the Screen-grid is connected to the negative AC terminal of the circuit and does not form a power takeoff element.

BUT because in ultra-linear configuration the transformer tap directly connects the external two circuits to the Screen-grid INSIDE the tube an entirely different set of operating conditions is formed when compared with conventional pentode operation. This changes everything.

The direct external connection to the Screen-grid causes the external series connected (via the transformer primary winding) Cathode to Screen and Screen to Plate circuits to be now connected in parallel with the Cathode to Plate circuit INSIDE THE ELECTRON TUBE.

It follows that the sum of their voltages at any instant in time MUST equal the internal Cathode to Plate voltage.

Now it can be seen in this example that if the Cathode is at 0 volts AC potential and the Plate is at 100% volts AC potential, by operation of the voltage distribution over the transformer primary winding, the Screen-grid MUST always have 43% (in this example) of the AC Cathode to Plate voltage at its terminal.

Reference to the above diagram shows the Screen-grid to Plate circuit inside the tube is also connected in parallel with the lower section of the transformer. Thus the output voltage developed across the Plate to Screen tap on the transformer - in the case of a 43% tap being 57% x the full AC output voltage across the primary - when re-injected in opposite phase polarity into the Screen-grid must inhibit electron flow.

That is the design purpose and operational effectiveness of the Screen-grid (when compared with conventional pentode mode) is affected because the 57% applied AC voltage reduces the effective Screen-grid voltage and therefore tube gain. For the purpose of explanation, this is not to be confused with negative feedback.

Furthermore, the Cathode to Screen-grid AC voltage is also fixed at 43% of the output voltage across the full transformer primary, again influencing negatively what is happening inside the tube, but in a different way. Another way of saying this is that the natural voltage distribution between Cathode and Screen-grid is changed by injection of AC signal to the Screen-grid.

In addition, the transformer load impedance has the effect of controlling current flow within the tube between Cathode and Screen-grid. This may explain the observations of Hafler and Keroes, as described in US Patent 2,710,312 referenced above, that as the Screen-grid tap increases from 0% turns to 18.5% turns the internal impedance of the tube reduces linearly then flattens off.

In the case of a push-pull amplifier the situation is worse because the reflected voltage from the opposite polarity tube is now out of phase with the internal electron flow.

From this one could deduce that the ideal configuration to maintain voltage balance in the output stage would be a 50% turns tap for the Screen-grid. Alternatively, to maintain impedance balance in the output stage between Plate and Screen-grid would require a 70.7% turns tap (50% impedance) for the Screen-grid. However it should be stated that none of the test reports quoted verifies this thought.

To overcome the above described shortcomings the core premise of my OPTIMISED ULTRA-LINEAR © design concept is that the AC and DC voltage gradient INSIDE the tube MUST exactly match the voltage gradient OUTSIDE the tube.

This sounds like a very simple concept but in the case of conventional ultra-linear design there is no attempt to match the internal AC voltage with the external AC voltage, or the internal DC voltage with the distribution of internal resistance within the tube.

The above diagramme shows that in an ultra-linear power amplifier circuit the output transformer becomes an auto-transformer, rigidly interconnecting the otherwise independent three circuits described above in a fixed relationship.

Traditionally, designers have ignored this however

there is always AC inside the tube whilst it is conducting signal.

WHY?

Because the Cathode to Plate electron stream forms the return circuit for the both the DC power source and AC output. There has to be a return circuit for current to flow.

The following diagram shows how this is so:

The output transformer and power tube are in series with the applied DC voltage from the power supply.

The conventional design paradigm is to ignore the transformer, so the DC voltage applied to the Plate and Screen-grid of the tube is assumed to be the total (100%).

However there is voltage loss in the transformer because the copper wire has significant resistance.

Since the DC voltage loss is in direct proportion to the Plate Current, it follows that as signal power output increases the Plate voltage decreases.

Similarly, the DC Screen-grid voltage will also fluctuate with signal power output.

Now the DC voltage loss in the transformer between Plate and Screen-grid will be in proportion to the SUM of Plate current plus Screen-grid current. It follows that since this value is greater than Screen-grid current alone, the Screen-grid voltage will fluctuate not in direct proportion to its own needs but in proportion to the total current in the circuit.

Therefore as power output increases so does current flow and so does voltage fluctuation at the Screen-grid terminal.

In a conventional transformer having the Screen-grid tap at 43% turns, the voltage drop at the Screen-grid terminal will be 43% of the total voltage drop across the transformer. In a transformer having a half-primary DC resistance of 250 Ohms, the DC voltage drop at 100 mA (eg KT88 - change in current from zero signal to max signal) will be 12.5 volts DC.

Since the Screen-grid controls tube gain it follows that the signal in the tube will be modulated by the fluctations in Screen-grid voltage. At 400 VDC this equates to a ripple voltage of 3%. This will be nominally doubled by the autotransformer effect on the Cathode to Plate circuit - or forced by the Plate to be dissipated in the transformer as induction loss.

This does not seem significant but if we are chasing 0.1% THD in the output stage then it is important.

This voltage fluctuation is in addition to the Plate voltage fluctuation. However the tube data sheets indicate fluctuation in Plate voltage does not affect current flow - but it does affect power output because power output = volts x amps.

Therefore in normal operation, although the Plate to Screen voltage ratio remains nominally constant, the Cathode to Screen voltage is not in direct proportion to the Cathode to Plate voltage.

Thus in a conventional ultra-linear circuit there is no way the Screen-grid DC voltage can be stable.

It can also be seen from the above analysis that the amplifier CANNOT reproduce dynamic peak signals faithfully.

Furthermore, the AC voltage in the power circuit behaves in a similar way.

That is, in addition to voltage losses caused by AC impedance in the transformer, there is also the mismatch between the internal and external AC signal circuit voltages caused by the direct connection from the screen-grid to the transformer.

Furthermore, in a push-pull amplifier both Screen-grids will be simultaneously fluctuating in gain modulating AC voltage.

Since the output transformer rigidly connects both sides of the push-pull amplifier in a fixed ratio relationship it follows that what happens in one half of the transformer will affect what happens in the other half. As noted above the transformer presents as an auto-transformer to the tube circuits so the impedance ratios will be fixed between the three circuits described above. Distortion in the Cathode to Screen-grid circuit - nominally 43% turns - will be multiplied to the Screen-grid to Plate circuit section of the transformer.

When negative loop feedback is added to the amplifier from the loudspeaker terminals an attempt is made to cancel out such distortions.

To summarise, it can be said that conventional historic ultra-linear technology has limitations and shortcomings. These were highlighted very early by Williamson and Walker, to name but one example.

However my OPTIMISED ULTRA-LINEAR © concept overcomes this adverse phenomenum.

HOW??

To understand the OPTIMISED ULTRA-LINEAR © concept it is vital to acknowledge that electric current flows through a conductor only when there is a CIRCUIT.

ie - if we have a positive and negative terminal connected to a DC source with a voltage between them, no current will flow UNLESS there is a complete CIRCUIT.

In a push-pull Ultra-Linear output stage, a vacuum tube is exposed to two sets of operating voltages simultaneously - the applied DC voltages needed to enable the tube to work, and the AC voltages applied to the input circuit (Grid #1) to enable signal amplification.

The DC voltage component represents the input power - ie DC voltage and current supplied by the power supply to the Cathode/Plate circuit, the Grid #1 (Control Grid) bias circuit and the Grid #2 (Screen Grid) bias circuit.

The tube Cathode/Plate circuit is shunt connected across the power supply so, assuming constant DC voltages from the power supply, the DC current through the tube is the load on the power supply - ie the tube itself is the DC load.

The AC voltage component is the audio signal. The loudspeaker, coupled through the output transformer, is the AC load on the tube. Therefore, for purposes of circuit analysis and simplicity, the primary of the output transformer is the load on the tube.

Another way of putting it is that there are two separate CIRCUITS - AC and DC - using the vacuum tube cathode to anode section of those circuits as a common shared device/current path.

Therefore the vacuum tube, as a conductor, forms PART OF an AC CIRCUIT and PART OF a DC CIRCUIT

Thus in a vacuum tube, both the AC and DC

current components are present in the tube CIRCUIT simultaneously.

Kirchhoff's

Current Law

The algebraic sum of currents entering and leaving any point in

a circuit must equal zero - ie no matter how many paths into and out of a

single point in a circuit, all the current leaving that point must equal the

current arriving at that point.

This means that in the case of an electron tube, the electron stream

across the space, or gap, between the Cathode and Anode of the tube is used to

pass both the AC and DC currents measured in the primary of the output

transformer.

Kirchhoff's

Voltage Law

The algebraic sum of the voltages around any closed path is zero

- ie the voltage drops around any closed circuit loop must equal the applied

voltages.

This means that BOTH the DC and AC voltages present across the internal tube gap are distributed evenly across the Cathode to Anode gap by means of the electron stream - ie there is an AC voltage gradient across the gap and a DC voltage gradient across the gap - simultaneously!!

However in conventional tube audio circuit design, the DC voltage within the tube is usually considered but not the AC.

The AC component has been historically regarded as being exclusively signal - that is a product of tube function and performance - ie the product of variation in plate current across the load - but not so much an inherent function of tube operation.

That is, the AC output has been regarded as a pseudo-alternating current, created by the variation in DC plate current across the load - eg output transformer primary winding - magnifying (amplifying) the AC signal voltage appearing at the Grid #1 terminal..

In fact, if AC appears across the load it must also be present in the same magnitude elsewhere in the same circuit - ie within the output tubes themselves.

Another way of saying this is that if AC is produced by a variation in plate current across the load, then that AC cannot flow unless there is a complete circuit. The output tubes provide the return circuit for the alternating current.

Hence when the tube is operated by means of introducing a signal into the Control Grid - Grid #1 causing a variation in Plate Current, there will always be AC and DC currents flowing simultaneously within the tube itself.

First, if we examine the electrode construction of a typical tetrode or pentode audio power tube we will see the Screen-Grid is always located close to the Cathode but far from the Anode (Plate). This means that when the voltage gradient across the electron stream in the tube is considered, the equilibrium, or naturally distributed, voltage between the Cathode and Screen-Grid will be proportionately small when compared with the equilibrium voltage between the Cathode and Anode.

Careful examination and measurement of a range of tetrodes and pentodes demonstrates that the manufacturers' maximum rated Screen-Grid and Plate Voltages for tetrodes and pentodes are generally (but not always) directly proportional to the actual physical distance between these tube elements.

Another way of saying this is that if we distribute maximum rated Plate

Voltage across the measured linear distance gap between Cathode and Anode,

the manufacturers' maximum rated Screen-Grid voltage usually (but not

always) directly correlates with the ratio of the physical gap between Cathode

and Screen-Grid to that of Cathode and Anode.

Second, if we consider the DC circuits in a push-pull ultra-linear output stage we will see that the Screen-Grids are connected to a tap in the primary of the output transformer.

The position of this tap was determined long ago by the experts to be optimised at 40-43% of turns, measured from the primary centre-tap terminal and the Anode terminal of each half.

Most importantly though, and disregarding voltage drop in the transformer windings, the DC voltage applied to the Screen-Grids is the same as that simultaneously applied to the Anode terminals and to the centre-tap terminal.

In other words, in a conventional ultra-linear output stage the

Screen-Grids are energised to the same DC potential as the Anodes.

Third, if we consider the AC circuit in the same push-pull ultra-linear output stage we will see that the Screen-Grids are connected to a tap in the primary of the output transformer - as for DC.

However because the return AC circuit to the Cathode is through the bypass capacitor at the transformer centre-tap terminal, the centre-tap terminal of the output transformer is effectively at AC earth potential for all frequencies in the circuit which, in a fixed bias amplifier, results in the centre-tap of the output transformer being effectively directly connected to the Cathode of the tube to complete the AC CIRCUIT.

Also, in the case of a sine-wave signal in a push-pull transformer output

stage, the centre-tap equates to the mid-point axis of the output signal and is

therefore, when connected to the Cathode via the bypass capacitor, also at AC

voltage zero - ie the output stage is "balanced" about the mid-point

being the centre-tap of the output transformer being at 0 volts AC potential.

OPTIMISED ULTRA-LINEAR © OPERATION.

Now, the Anode and Cathode of the tube form the positive and negative electrodes for both DC and AC voltages across the tube, separated only by a physical gap.

The assembly is mounted in a vacuum dielectric so current will flow between

the electrodes only when there is an electron stream between them.

OHMS LAW

If a current flows between two points in a conductor across which the potential difference is E, then E/I is a constant - which is known as the resistance R - between the two points.

Hence R = E/I

In the case of a vacuum tube, its PLATE RESISTANCE (rp) is defined as being the resistance of the path between Cathode and Plate to the flow of alternating current. It is the quotient of a small change in Plate voltage by the corresponding change in Plate current and is expressed in Ohms, the unit of resistance. Thus a change of 0.1 mA (0.0001 A) is produced by a Plate voltage variation of 1 volt, the Plate resistance is 1 divided by 0.001, or 10,000 ohms. (ref RCA RC-14)

If we now consider the AC signal output voltage distribution across the vacuum tube we can easily see that the AC voltage gradient across the tube will be the same as that across the half-primary of the output transformer - because the half-primary AC impedance is the actual load on the tube. That is to say the transformer is connected directly across the tube terminals - one end to the Anode, and the other to the Cathode, through the negligible impedance B+ supply bypass capacitor.

In this case R = the resistance of the internal Cathode to Anode gap in the tube.

It follows then that when a 43% turns transformer tap is used to feed the Screen-Grid, the AC voltage applied to the Screen-Grid by virtue of its position in the electron stream, is 43% of the Cathode to Anode signal voltage.

Similarly, if an alternate portion of AC signal output voltage is tapped from the output transformer (eg 50%) then the same portion will be applied to the Screen-Grid.

This proposition might be better understood by envisaging the tube as a voltage-divider. The Anode and Cathodes are the positive and negative line terminals respectively and the Screen-Grid terminal is the load tap-off point.

Therefore, in a conventional ultra-linear output stage having equal Anode and Screen-Grid DC voltages we have a serious mismatch between the AC conditions and the DC conditions.

ie the AC signal voltage injected to the Screen Grids via the transformer

tap is only 43% of the Cathode to Anode voltage but the applied DC voltage to

the Screen Grids via the same tap is 100% of Anode voltage.

Historically, this AC voltage has been regarded simply as "negative feedback" contributing to improving the circuit's performance, rather than a factor in tube behaviour.

Furthermore, in the case of DC voltage in a conventional ultra-linear output stage , the Screen-Grid is over-excited because its applied voltage is the same as that applied to the Anode, requiring increased negative bias voltage to Grid #1 to offset the increased current flow in the tube.

This phenomenon is particularly evident in the KT88 beam power tetrode,

which has a physical construction conforming to the 43% ratio as described, but

has been assigned manufacturers' Plate and Screen-Grid voltage ratings

inferring a tube behaviour something quite different to that.

Now in the case of AC voltage, the actual Screen-Grid voltage is automatically determined by the fixed position/ratio of the Screen-Grid tap on the output transformer - typically 43% of output signal voltage - resulting in full B+ DC voltage but only 43% of AC signal voltage being present upon the Screen-Grid at the same time.

Although the AC voltage derived from the output transformer Screen Grid tap is of opposite polarity or phase to the current in the tube and, when coinciding with a 43% portion of actual tube signal voltage at the Screen-grid, will be of equal magnitude (potential) to the voltage in the tube at that point, it is apparent that such a condition is essential to ideal ultra-linear operation and performance.

The effect of mismatching the feedback signal voltage with the actual voltage in the tube is not clear but it is assumed that some of the energy would be consumed as waste heat - an undesirable outcome. Tube instability might be another result. Increased distortion will be a definite outcome.

Linearity will also be definitely affected because the effect of the AC

signal component upon Screen-Grid operation, and therefore tube gain, will

increase as the signal amplitude increases. In other words, as power output

increases the effects from the AC/DC mismatch will increase.

To correct these anomalies it is desirable to do three things:

1. Apply a DC voltage

to the Screen-Grid that is within the tube rating - ie not exceed rated maximum

Screen-Grid voltage - to reduce stress and prevent over-excitation

2. Optimise both DC

and AC simultaneous conditions - ie to ensure the Anode voltage cannot fall

below the

Screen-Grid voltage during any part of the signal cycle, apply a DC voltage to the

Screen-Grid that is

consistent with and directly proportional to the AC signal voltage ratio (eg

43% of Plate voltage)

3. Use a tube that

has its internal element ratio consistent with the above - ie the physical gap

between Cathode

and

Screen-Grid to be 43% of the gap between Cathode and Anode.

To fulfil the above criteria we need to select a tube that is capable of operating OPTIMALLY when its Screen-Grid is at 43% of the ACTUAL Plate voltage for both DC and AC components.

This requirement can only be achieved by tubes having their Screen-Grid located in a fixed physical relationship with the Cathode and Anode such that the Screen-Grid is located at 43% of the gap between Cathode and Anode.

Importantly, Hafler and Keroes of Acro USA (1951) determined an optimum 43% ratio for the 6L6 and 807 families of tubes - later incorporated into the modified Williamson ultra-linear amplifier designs.

GEC/MOV Co. (1959) later determined that this optimum 43% ratio also applied to the KT88/TT21/TT22 families of tubes.

The following graph, courtesy of GEC and AWV Radiotronics Magazine (June 1959), shows the comparative characteristics of the KT88 in triode, pentode and ultra-linear connections using selected TURNS ratios for the ultra-linear output stage configuration.

This graph very clearly shows that the optimum

ratio is 43% turns (19% impedance).

WHY 43% ?

Up until now, nobody has provided a detailed theoretical basis or explanation for the ratio of 43% being the optimum for most popular power tubes.

Recent research by Rudolf Moers, a distinguished Electrical and Electronics Engineer located in the Netherlands, tells us very explicitly - why it is so.

Mr. Moers has graciously made available for us his wonderful recent scientific investigation into the design theory and practice of Ultra-linear audio amplification.

These papers are posted with permission from Linear Audio www.linearaudio.net and their author Rudolf Moers.

Part 1 - Power Point presentation

Part 2 - Power Point presentation

Parts 1 and 2 of the above Power Point presentations - combined in pdf format

Paper - The Ultra-Linear Power Amplifier: An adventure between triode and pentode - pdf format

The engineering design methods developed by Mr Moers may be used to

determine theoretical plate/screen load ratios for ultra-linear operation of

power tubes.

Tube Selection:

Tube selection can be readily determined by examining tube ratings, because the maximum rated Plate and Screen-Grid voltages are generally directly proportional to the physical spacing of the elements within the tube.

If we want to optimise the design of our ultra-linear audio amplifier for absolute maximum performance there are few tubes that have the exact ratio of Cathode to Screen-Grid and Cathode to Plate voltage that we need.

HOWEVER TO BE SURE, IT IS NECESSARY TO PHYSICALLY MEASURE THE ELECTRODE

SPACING WITHIN EACH TYPE OF TUBE.

At this point in time and on available information I am able to identify only a small selection of tubes that by their internal construction fulfil our criteria for OPTIMISED ULTRA-LINEAR © OPERATION.

For audio applications the following tube types offer nearly an exact match

when standard tube tolerances are considered.

300 VDC Maximum Plate Voltage and 125 VDC Maximum Screen-Grid Voltage

5618

500 VDC Maximum Plate Voltage and 200 VDC Maximum Screen-Grid Voltage

837

600 VDC Maximum Plate Voltage and 250 VDC Maximum Screen-Grid Voltage

6146 series

6159 series

6293

6883 series

7212 series

8032 series

8552 series

8298 series

6DQ6 series (receiving tube version of the 6146)

QE05-40 series

QV06-20 series

Note: The above set of 6146 based family of tubes have identical plate

characteristics and require a standard octal socket.. Variances relate to

heater voltage, plate dissipation, construction, pinout and ruggedised

construction.

TUBES FOR HIGHER OUTPUT POWER:

For the adventurous and brave-hearted who require higher power output the

following tubes are available for operation at up to 2250 VDC CCS Plate

voltage.

1000 VDC Maximum Plate Voltage and 400 VDC Maximum Screen-Grid Voltage

814

In this case I would recommend reducing the applied Plate voltage to 1000

VDC from the maximum rated 1500 VDC, to precisely align with the actual

Plate/Screen physical tube gap ratio.

1250 VDC Maximum Plate Voltage and 600 VDC Maximum Screen-Grid Voltage

TT21 (GEC, Marconi etc)

TT22 (GEC, Marconi etc)

1500 VDC Maximum Plate Voltage and 600 VDC Maximum Screen-Grid Voltage

803

In this case I would recommend reducing the applied Plate voltage to 1500

VDC from the maximum rated 2000 VDC, to precisely align with the actual

Plate/Screen physical tube gap ratio.

1750 VDC Maximum Plate Voltage and 750 VDC Maximum Screen-Grid Voltage

828

The 828 has a maximum rated Screen Grid voltage exactly 43% of the rated

Plate Voltage.

2250 VDC Maximum Plate Voltage and 900 VDC Maximum Screen-Grid Voltage

813

In this case I would recommend reducing the applied Screen-grid voltage 900

VDC to precisely align with the actual Plate/Screen physical tube gap ratio.

Important:

All these high-output power tubes have a top anode cap and require insulated anode caps and wiring to prevent electric shock to users.

All these tubes get very hot and require adequate ventilation.

Plate and Screen-grid connection lead lengths must be kept as short as is practicable to prevent RF oscillation

Excepting for the TT21 and TT22, all the above tubes are directly heated filament types

Output transformer windings must be capable of handling the peak signal

condition Plate and Screen-grid DC currents respectively

OUTPUT TRANSFORMER

It will be evident that if the Screen-Grid is to be supplied with a DC voltage of only 43% of the Anode voltage, then a separate winding is needed for the Screen-Grid connection. This is called a "tertiary winding".

Such a hi-fi transformer is available in a 120 W RMS rating, being the Acrosound TO-350 (6600 ohms PP) and Dynaco Type A-441 (4300 ohms PP).

Equivalents are currently available from some high-quality transformer manufacturers - eg Sowter Type 8994 and Amplimo PAT-2100-SSCR.

Also applicable is the hi-fi Dynaco A-440 (? ohms PP) transformer, being suitable for up to 300 W RMS.

A more recent development is the Pearl SC-280 transformer, designed for high-power hi-fidelity applications.

The design of an ultra-linear audio amplifier having a separate Screen-Grid supply is demonstrated by the Acrosound 100W 6146 and the Bruce de Palma 300W EL34 and the McIntosh MC3500 and MI-350 high-fidelity amplifiers.

The McIntosh MC3500 and MI-350 use four pairs of 6LQ6/6JE6B power tubes in a "balanced" push-pull arrangement, with a regulated supply to the Screen-grids. It also incorporates push-pull driver stages throughout and no loop negative feedback from the loudspeaker. It is not however an "ultra-linear" amplifier in the Hafler and Keroes definition - but it does achieve a similar effect by other means. A truly mighty amplifier.

Note however that the voltages used in these designs do not correlate with the optimal design criteria proposed above.

In the case of the Acrosound, the Anode voltage would need to be reduced to 600 VDC, and Screen-Grid voltage to 250 VDC (with some loss of power output), to fulfil the 43% voltage ratio at maximum rated Screen-Grid voltage.

In the case of the Bruce de Palma EL34 design having an anode voltage of 1,000 VDC, the Screen-Grid voltage would need to be reduced to 430 VDC to fulfil the 43% voltage ratio at maximum rated Screen-Grid voltage.

In terms of applied Screen-grid voltage, the McIntosh MC3500 is already very

close (38%) to being optimised to my OPTIMISED

ULTRA-LINEAR © concept (together with other more complex output

stage refinements) but the output transformer turns ratio is not available - so

unless you have access to the level of instrumentation and expertise essential

to tweaking this complex amplifier it would be wise to leave it as manufactured

to original McIntosh specifications. In practical terms, in my humble opinion,

it is unlikely even the most critical listener would be able to discern the

difference.

OTHER OPTIONS.

If the Screen-Grid tertiary winding ratio on the output transformer is increased to 50% of turns, then other tube types become available as viable options for OPTIMISED ULTRA-LINEAR © OPERATION.

Tube Type Plate Volts Screen Volts

2E24

400

200 (directly heated filament type)

2E26

400

200

802

500

250 (directly heated filament type)

807

600

300

815

400

200 (815 = 2 x 2E26 in one botlle)

1610

400

200

1624

600

300 (directly heated filament type)

1625

600

300

6BG6GA

600

300

6W6GT

300

150

The GEC graph shown above suggests that using a 50% tap, power output will be down about 10% on the 43% tap performance, however output impedance is lower.

On the other hand, according to manufacturers' data, the above tube types

offer maximum output at 50% Screen-Grid voltage.

RULES FOR OPTIMISED ULTRA-LINEAR © OPERATION:

1. Plate to Screen-Grid Voltage Ratio

Irrespective of actual DC

Cathode to Plate voltage, the applied DC Screen-Grid voltage must always be

maintained at 40% to 50% of

actual applied DC Plate Voltage

2. Transformer Ratio

The applied DC Screen-Grid

voltage must be in approximately the same ratio to Plate Voltage as the actual

Transformer Screen-Grid turns-ratio

tapping point used.

3. Transformer Tapping Point

The Transformer Screen-Grid

tapping point, when expressed as a proportion of the whole half-primary

turns, must match the

physical gap ratio of the Cathode to Screen-Grid and Cathode to Anode elements

in the

tube type used.

4. Ideal Tube Operation

Each type of tube has an

ideal or optimal operating point for OPTIMISED ULTRA-LINEAR ©

OPERATION.

The optimal operating point will be that portion of turns

ratio matched to the tube physical and electrical characteristics that

provides optimal performance.

This can be determined by

reference to tube handbooks/catalogues and identifying the recommended

Screen-Grid operating voltage. This

is usually constant for the full range of recommended plate voltages.

Except where otherwise

determined by physical measurement of the tube gap ratio, to determine optimum

Plate

voltage multiply the applied

Screen-Grid voltage by 100/43 (2.32558)

This will be the optimum set

of Plate/Screen voltages for OPTIMISED ULTRA-LINEAR ©

OPERATION.

It is obvious then that if a particular tube type is

preferred then its physical characteristics need to be determined before

determining transformer ratio and applied Screen-Grid DC

voltage.

eg RCA Transmitting Tube Manual TT4 indicates the type

6146 tube has a recommended Screen-grid voltage of 175 VDC

for all recommended typical operating conditions - ie Plate

voltages set between 400 and 750 VDC.

To determine the ideal Plate voltage for OPTIMISED ULTRA-LINEAR © OPERATION multiply 175 x

2.32558 = 407 VDC. Therefore the optimum operating condition

for tube type 6146 is 400 VDC on the Plate and

175 VDC on the Screen-Grid.

Experiments have shown me that these voltages are very

satisfactory for the 2E26 and 6146 types of beam power tubes

- both of which have aligned Screen-grids.

Neither the 2E26 or the 6146 will work in conventional

ultra-linear mode (even at low voltages) and self-destruct due to

excessive Screen-grid current (irrespective of Grid #1 bias

voltage) - even at relatively low plate/screen voltages - ie 300

VDC.

My experiments have shown also that neither of these tubes works satisfactorily for hi-fi in triode connection either.

However in OPTIMISED

ULTRA-LINEAR © OPERATION their performance

is spectacular, providing rich,

clean, powerful sound of

magnificent tone!!

Both the 2E26 and the 6146

family are in my opinion two of the very best hi-fi tubes available when

connected as described

above.

When used in parallel-push pull

configurations they offer high power from very little AC signal driving

voltage.

* * *

IMPORTANT: It may be noticed that in the above listing the ideal operating voltage for the Screen-Grid is set at the manufacturer's recommended Screen-Grid voltage and not the Rated Maximum.

This is because the Screen-Grid requires a certain voltage to do its job best - ie to attract electrons from the Cathode and accelerate them towards the Plate. It is usually low in relation to the applied Plate voltage and is invariably less than the rated maximum Screen-grid voltage.

That voltage is determined by the tube manufacturer and is usually published

in the tube data handbooks.

Note: Before deciding what transformer primary tap ratio to use it is essential to physically determine the actual Screen Grid to Anode space ratio.

In most cases this can be easily done without having to destroy a valuable tube. Just measure the spacing between Cathode and Anode and of the grid support pins at the top of the tube. In the case of beam power tubes this may be difficult because there is usually a box-like assembly covering the Plate structure. But a bit of ingenuity should solve the problem

If it becomes necessary to destroy a tube to examine its internals safety precautions must be observed:

1. Wrap the tube in a strong cloth

2. Place the tube in a vyce and squeeze the glass bottle

slowly until it implodes

or

3. Gently hit the glass with a hammer at a point not directly

over the electrode assembly

4. Carefully remove the broken glass and dispose of safely

5. Carefully cut away the electrodes until the elements can

be measured

* * *

RECOMMENDED CONFIGURATION

For those who wish to build the ultimate in OPTIMISED ULTRA-LINEAR © I would recommend the following configuration:

OUTPUT TRANSFORMER - High Fidelity

Primary winding for plates - 100% plate to plate load impedance and comprising FOUR separate sections each having equal turns. Connect two windings in series for each half.

Tertiary winding for screens - 50% of Plate to Plate Primary winding TURNS and comprising TWO separate sections each having equal turns.

The primary and tertiary sections are therefore of equal turns.

Secondary winding - 5 separate sections or 7 separate sections having equal turns and interleaved with the primary and tertiary windings. Connect in SERIES to make up full loudspeaker matching impedance.

Why 50% ratio??

Because it makes transformer design and manufacture simple (easier to count the same number of turns for each winding during manufacture), provides more flexible connection options, increases the level of AC signal feedback to the Screen-grids (increasing the damping factor), reduces the output impedance very slightly and provides better tone (than 43% turns tap).

A slight loss of power may be measured compared to

the 43% configuration but with four pairs of tubes as recommended that should

not be a problem.

OUTPUT TUBES - FOUR pairs of tubes in parallel-push-pull

This has the effect of reducing the output

impedance to one quarter of that for one pair of tubes.

This has the effect of reducing the transformer turns

ratio to one sixteenth of that for one pair of tubes.

AC signal drive voltage is the same as for one pair

of tubes enabling cathode-follower drivers to be utilised (recommended also) -

see GEC 400W amplifier circuit for a typical configuration.

A proportionately larger final filter cap is

recommended to provide the extra current needed to handle transient signals -

eg 500 uF.

Preferred output power tube type - BEAM POWER TETRODE TUBE with aligned grids

My picks for best results are:

2E26

6146, 6146A,

6146W, 6146WA, 7212

6146B/8298A

6159, 6159A, 6159B (26.5V)

6293 (check ratings)

6883A/8032 (12.6V)

6883B/ 8032A/ 8552 (12.6V)

807

813 (10V filament)

All have a top anode cap.

All are of broadcast/military quality and offer extra

features (such as ruggedised construction and reliability) compared to

domestic/receiving quality tubes.

Both the 2E26 and 6146 require a standard octal

socket.

Both the 2E26 and 6146 have relatively large

cathodes.

The 807 requires a 5 pin socket.

The 813 requires a giant seven pin socket.

All the above are readily available in vintage NOS

or used condition and at affordable cost.

Other Options

If no anode cap is permissible then consider the more recently developed KT90 tube

Its manufacturer, the "Ei-RC" - Electronic tubes factory" recommends a maximum Plate and Screen-grid voltage of 650 VDC for conventional ultra-linear, however the plate voltage can be increased to 750 VDC for pentode connection.

Consequently for OPTIMISED ULTRA-LINEAR © operation,the conditions may be set to up to 750 VDC Plate and 300 VDC Screen-grids.

However this high Plate voltage may lead to flashover at the octal pin socket, hence it is recommended that the Plate voltage be limited to 600 VDC and Screen-grid to 250 VDC

The KT90 is recommended by Ei-RC as a replacement for 6550, 6550A and KT88 however, to optimise performance, the operating conditions must be adjusted to suit the KT90 characteristics.

Of course OPTIMISED

ULTRA-LINEAR © will work with the more

popular but lesser performing tubes such as EL34, 6L6GC, KT66, KT88 and 6550 provided

the Screen Grids are terminated to a separate tertiary winding and supplied at

a DC voltage being not more than 43% of Plate voltage.

PLATE AND SCREEN GRID VOLTAGES:

With the above described transformer arrangement DC

Screen grid voltage will be set at 50% of the DC Plate voltage.

FURTHER ENHANCEMENT:

MULTIPLE LOUDSPEAKERS

Use multiple loudspeakers connected in series. This increases the total load to the amplifier, thereby reducing the transformer ratio to a relatively low order, enhancing fidelity and tone.

It also has the effect of reducing total effective loudspeaker capacitance and increasing total effective loudspeaker inductance as presented to the amplifier. This increases stability and linearity in a vacuum tube amplifier - but maybe not in a solid state unit.

Using four tubes in parallel and four speakers in series enables a transformer to be used that has only one quarter of the turns ratio needed for a conventional single pair of tubes driving a single loudspeaker configuration (having the same single unit impedance).

eg 8000 ohms P/P to 8 ohms

requires a transformer having a turns ratio of 31.6

2000 ohms

P/P to 32 ohms requires a transformer having a turns ratio of only 7.9

Clearly if more speakers, or 16 ohm speakers instead of 8 ohms are used, then the situation can be improved proportionately.

My current output transformers are 2500 ohms P/P

to 64 ohms, requiring a turns ratio of only 6.25:1

In a conventional arrangement the ratio would be

10,000 ohms to 8 ohms, requiring a turns ratio of 35.4:1 - nearly six times

worse.

Such a configuration offers better performance from the same standard components as used in a conventional single-pair amplifier.

Naturally, transient response is excellent!!

NOTE: All the above

comment refers to an amplifier having no interstage negative feedback - eg from

the output transformer secondary winding to a previous stage.

*

*

*

IMPORTANT NOTICE

THE AUTHOR MAKES NO CLAIM WHATSOEVER AS TO THE VALIDITY OR ACCURACY OF ANY STATEMENT, INFORMATION OR OPINION CONTAINED IN THESE PAGES AND NO LIABILITY WILL BE ACCEPTED FOR ANY ERROR OR OMISSION OF ANY KIND WHATSOEVER.

PLEASE NOTE NO WARRANTY IS EXPRESSED OR IMPLIED

AS TO THE WORKABILITY OR PERFORMANCE OF DESIGN INFORMATION DESCRIBED HEREIN.

© NOTICE: INTELLECTUAL PROPERTY COPYRIGHT D.R.GRIMWOOD 2002 - ALL RIGHTS RESERVED.

NO PART OF THIS TECHNOLOGY MAY BE USED FOR COMMERCIAL PURPOSES IN ANY FORM WHATSOEVER INCLUDING BUT NOT LIMITED TO PRODUCT DEVELOPMENT OR GAIN OR REWARD WITHOUT THE EXPRESS WRITTEN PERMISSION OF THE AUTHOR.©

Intellectual property in the applied

engineering concepts expressed in this paper remains expressly and exclusively

with the author.

This page last modified 29 December 2017

This page is located at http://www.oestex.com/tubes/ulo.html