Oestex ©

GUITAR

AMPS PAGE

SECTION 8: CHASSIS AND COMPONENT LAYOUT AND WIRING

CHASSIS AND COMPONENT

LAYOUT AND WIRING

Review of past design practice shows us that

many designers had no idea of the principles essential to optimising chassis

layout.

In a wide range amplifier, the wiring and

componentry act as antennae, to pick up stray and induced signals, such as

ultrasonics, RF, hum and noise, from adjacent circuitry.

The basic rules for component layout and

wiring are:

·

do not mount electrolytic capacitors close to tubes - the caps will dry

out and fail

·

do not mount electrolytic capacitors close to transformers - the caps

may induce hum and interference into the B+ bus

·

do not mount hot tubes near transformer windings - the windings will

burn or dry out

·

do not mount driver stage tubes near transformers or mains wiring - to

avoid induced interference or hum

·

do not mount transformers close together - eg side by side. If this is

not practicable mount the transformer cores at right angles to each other to

minimise magnetic interaction

·

do not mount power transformers near signal leads or unenclosed

components such as a magnetic pickup cartridge - in the case of pre-amplifiers

this may mean a physical separation of a couple of feet - ie half a metre.

Generally speaking, the larger the transformer the further the magnetic field

will extend.

·

do not mount exposed driver tubes near output tubes or rectifier tubes -

they may pick up induced signals such as RF, hum and even audio, and trigger

parasitic oscillation in the circuit

·

do not mount tubes near the edge of the chassis - they can burn the

enclosure or cabinet when the chassis is installed and operating

·

do not mount input wiring near output wiring either within a stage or

across stages - to avoid stray signal induction or oscillation

·

do not mount input terminals near speaker terminals or mains supply

leads or plugs - to prevent instability and/or interference from induced

signals

·

do not mount tubes upside down without restraining devices - they can

fall out partially, with loss of one or more contact pins, or completely fall

out and break

·

do not mount tubes horizontally unless their grid wires are installed in

the vertical plane - to prevent grid wire sag when hot and thus uneven electron

flow, or internal shorts

·

always use shielded wiring for signal pathways in the early stages - to

prevent stray hum and noise pickup and induced feedback signals

·

never ground potentiometer wires to the chassis at the potentiometer -

always ground directly to the relevant cathode (through a shielded co-ax lead)

·

always shield input tubes with discrete shields or a grounded metal

enclosure (there are currently more than 100 million mobile telephones in the

world, thousands of radio and television transmitters and significant numbers

of high-powered industrial and military transmitters, and they do generate a

significant amount of RF energy for your hi-fi amp to pick-up)

·

always mount tubes as close to each other as space will permit - to

minimise wiring length and minimising exposure to induced signals or

interference (but always leave at least a 10 mm gap between bottles for natural

air cooling - more for larger tubes having more than 25 watts plate

dissipation)

·

always use short leads between connection points - to minimise wiring

length and minimising exposure to induced signals or interference

·

never connect pins on tube sockets directly together with straight or

solid or heavy wire unless there is a loop to enable each socket pin to locate

properly about its tube pin - tube pins do not bend well to match socket

misalignment, so some movement in the socket terminals is essential

·

always mount tube sockets such that the heater pins are aligned with the

direction of wiring - to minimise heater lead length

·

always twist heater wires together - to neutralise AC radiation to

nearby wiring and components (cancel-out hum signals)

·

always ground grid and cathode resistors (and bypass caps where

applicable) to the cathode pin, if grounded, or to the grounded end of the

cathode resistor. One very effective technique is to instal the resistors

vertically, straight up from the socket pins, then simply join the ends to be

grounded together (neatly). Connect them via a wire to chassis ground. This

bundle of components does not need further support as they are a strong

structure mounted directly from the tube socket. Some miniature sockets have a

centre tube spiggot for shielding the pins from each other - this should be

also grounded. The tube shield provides a useful structural support

·

where practicable, instal interstage capacitors with the outer layer

connected to the previous stage plate - to minimise hum pickup Vintage caps

often had a band printed on one end to indicate the outer layer

·

try to layout the chassis following the circuit diagram (schematic) -

this method actually works!!

·

ensure the amplifier is well ventilated - to ensure adequate cooling and

to facilitate long-term component life

·

always insulate and isolate high voltage and mains power circuitry -

death is permanent!!

·

always use an isolating transformer between the mains power source and

the rectifier and heater/filament system (to prevent electrocution)

·

always insulate and isolate high voltage capacitors - particularly

large capacitance units - they can store electrical energy for several days. An

amplifier switched off may still be hazardous or even lethal

·

always use an enclosed METAL chassis system - if necessary fit a

removable lid/cover for component access. 20 gauge galvanised steel sheet (1

mm) thick is ideal but aluminium is more suitable for large chassis to reduce

weight. Note that it is not possible to solder components to aluminium using

tin/lead solder so all chassis joints must be tightly screwed together.

·

never use 50/50 tin/lead solder - that is for plumbers. Use only a high

quality 60 tin/40 lead solder having a cored flux. To prevent dry joints

(imperfect metallurgical joint bond) when soldering components always allow

time for the joint to thoroughly heat before removing the soldering iron.

Printed circuit board conducting strip tends to separate from the

bakelite/fibreglass base board if overheated - best to avoid them. Take care

not to overheat plastic covered components.

·

always ground or earth the chassis (to prevent electrocution)

·

the earth side (outer shielded cover) of the input shielded lead must be

grounded to the amplifier chassis to prevent hum pickup, however modern

television receivers do not have an isolating power transformer and use a

"hot" chassis system. This means that if you connect yourself - or

someone else - between the TV chassis and ground there is a high likelihood of

death. If connecting audio signal leads to a TV receiver or similar device

ensure there is an isolating capacitor in series with each lead - ie both live

and earthed input leads, to prevent direct connection between the amplifier and

the hot (ungrounded) source. If you are not qualified to do this then take your

system to a qualified technician - you only have one life!!

·

always use wire having a cross-sectional area adequate for the current

to be carried. To minimise voltage drop and wire heating effects, it is

desirable that Heater wiring should be arranged so that each heater is wired

directly to the source transformer, rather than sharing a common pair of wires

for all tubes.

·

always twist Heater wiring together, to minimise the AC field around the

wires.

·

always use 105 deg C rated wire. This produces a better looking result

because the wire will not melt when soldering the conductor ends.

·

always try to use common wire colours for discrete circuit functions

·

when using filter capacitors in series, always bypass with equal value

bleed/bypass/voltage equalising resistors. If resistors are not installed the

capacitors will self-balance, which may result in one being subjected to

excessive voltage leading to failure.

·

always use speaker cables having as high a cross-sectional area of

conductor as possible (one Ohm of resistance in a 4 Ohm system - ie 0.5 Ohm in

each conductor - produces a 25% loss of voltage and a 25% loss of power at the

loudspeaker terminals)

· Note: The above rules are not listed in any

particular order.

.

.

The

following tips for construction and wiring were provided in 1938 by the

Partridge Transformer Company UK.

.

It

seems most of that advice was ignored by commercial designers.

. .

Partridge Transformers Notes on Amplifier

Construction 1938.pdf (click to

view)

.

AN EXAMPLE:

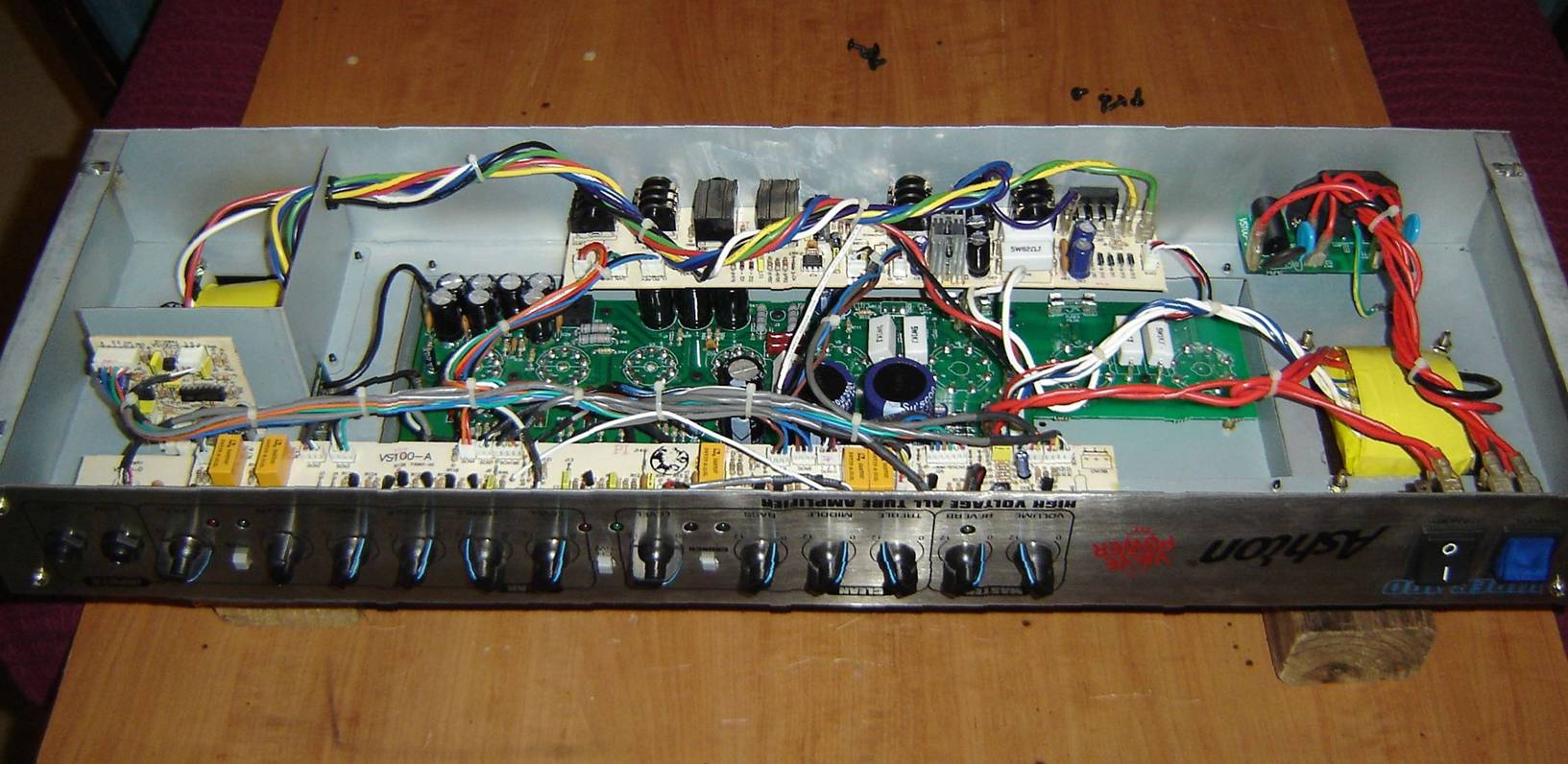

Here

is a 100W tube guitar amplifier similar to a Marshall JCM800 Head.

It

has 4 x EL34/6CA7 power tubes and 4 x 12AX7 preamp tubes.

The

first picture is of the amp “as-built”. The amplifier was unstable and

self-oscillating at an ultrasonic frequency.

Top front view.

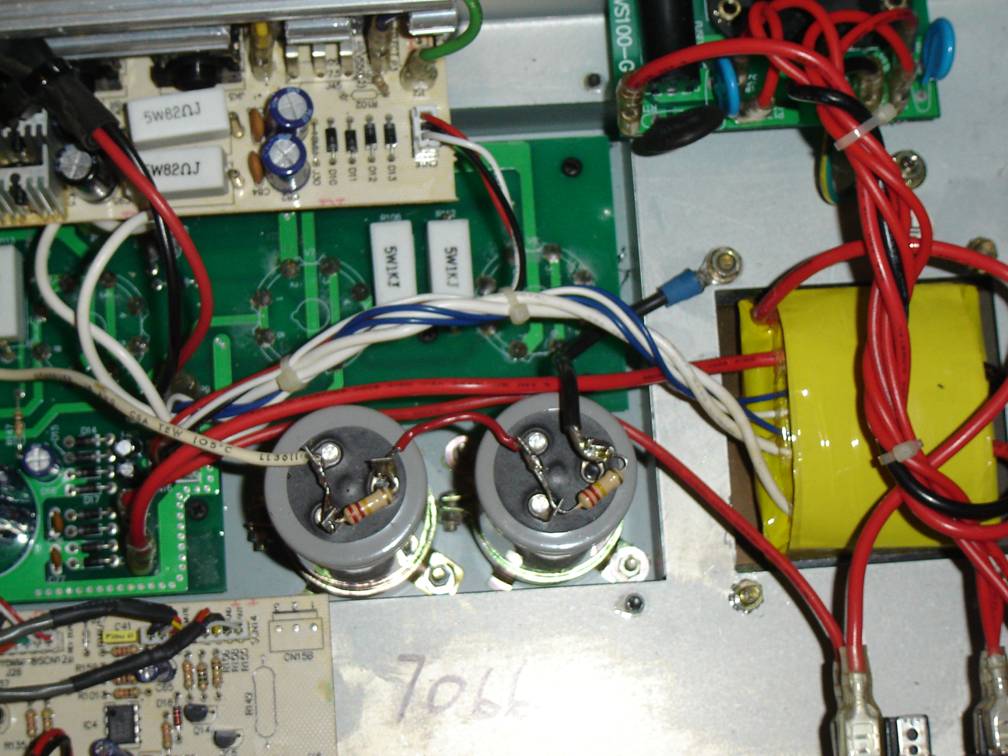

Top rear view:

Underchassis view showing

bundle of HV plate leads (red and blue) (white OT B+ centre-tap), and speaker

wiring (other colours) draped over preamp section and input circuitry at rear

of chassis – a recipe for self-oscillation.

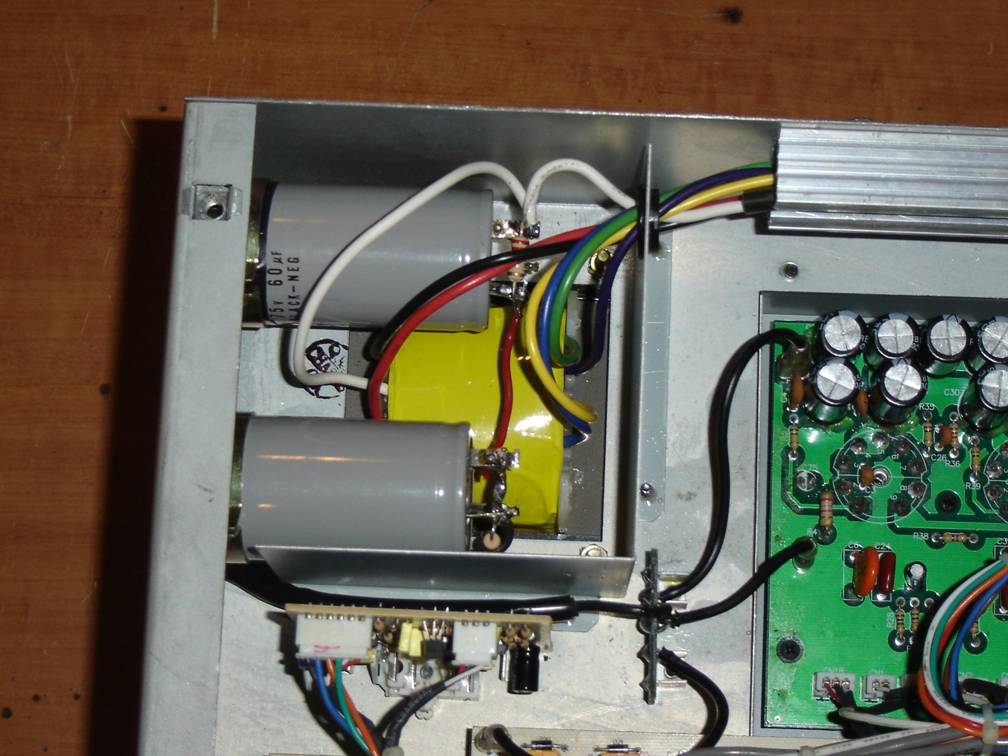

Power supply strengthened – an extra 260 uf x 4 pieces – two

at power transformer end and two inside OT shielded box.

The purpose was to reduce hum, improve clarity of sound and

increase dynamic response.

Aluminium channel section shield installed to rear of chassis

and hv wiring installed inside the channel

All sockets on rear panel now shielded. The amplifier is now

stable.

The design of this amplifier follows

longstanding industry practice intended to balance the weight of the head unit when

the carry handle is centrally mounted in the top of the cabinet.

The effect of this choice is to cause

long leads to be installed from the power supply to the output transformer,

usually close to rear panel sockets as in this example.

The effect of this is to expose

effects loop circuitry to power tube, output transformer and speaker circuitry

– effectively placing sensitive inputs next to or touching output wiring and

components.

You will also see long shielded

cables running all the way across the PCB to the right side of the preamp PCB.

In this example, if the output

transformer was mounted adjacent to the power transformer (with 90 deg

orientation of the lamination stacks) the preamp section could be moved to the

opposite end of the chassis by at least 6 inches (152 mm), thereby completely

separating HV sections from preamp sections. A thin sheetmetal shield from

front to back of chassis to shield the preamp section would be beneficial.

The carry handle is then moved to the

centre of gravity near the transformers.

The four extra filter caps could

still be mounted between the transformers and the chassis.

Also the rear PCB could be moved to

the left away from the power supply and output stage section.

STEP 13: SWITCH THE

AMPLIFIER ON AND LISTEN TO THAT SWEET, CLEAR TUBE SOUND!!

These articles, courtesy of Electronics

Australia, June 1983 edition, may cause you to reconsider what you are actually

hearing!!

A NOTE OF INSPIRATION:

For those who want to be different and own

and use tube amplifiers for their hi-fi - notwithstanding their

shortcomings and limitations - good luck to you and enjoy what you have.

If you feel inspired to improve what you

already have then hopefully these pages will have helped in your quest.

There is no restriction or cost imposition

upon the home hobbyist constructor to using these concepts - the only

restriction is on commercial exploitation where copyright is applicable - so if

you do not like it do not do it.

If you want your hi-fi to improve its

performance at minimal cost to you then experiment. The concepts presented here

do work and cost very little to implement.

However to those who say that a product is

only as good as what you pay for it, then these concepts are of no value to

you because they are free. You would be wiser to spend a hundred grand on a

commercial system and feel better. While you are so doing, ask the manufacturer

to justify the circuit design parameters and component choices to you.

Thank you for reading and considering my tube

hi-fi ideas as expressed in these pages.

Please let me know if you can add to this

body of tube hi-fi knowledge and I will add it to this commentary, which is

intended to communicate the results of my personal research and experimentation

over about 50 years of my life.

HAPPY CONSTRUCTING!!

MAY YOUR PROJECT BE A

SUCCESS!!

SAFETY WARNING:

DO NOT attempt to design

and/or construct a vacuum tube audio amplifier unless you suitably skilled,

qualified and/or experienced.

The Author makes no claim

whatsoever as to the validity or accuracy or otherwise of any statement,

information or opinion contained in these pages and no liability will be

accepted for any error or omission of any kind whatsoever.

Proceed only at your own

risk!!

No warranty of any kind

is expressed or implied as to the workability or performance of designs,

concepts or equipment described herein.

Never forget Murphy's Law: IF SOMETHING CAN GO WRONG IT WILL !!!!

·

VACUUM TUBES AND

CIRCUIT COMPONENTS OPERATE AT HIGH VOLTAGES OF BOTH ALTERNATING CURRENT AND

DIRECT CURRENT THAT CAN BE FATAL.

- VACUUM TUBES OPERATE AT HIGH VOLTAGES – UP TO

1,000VDC - AND TEMPERATURES THAT CAN CAUSE PERMANENT INJURY,

DYSFUNCTION OR DISABILITY - TO YOU OR SOMEONE ELSE.

- DO NOT ATTEMPT TO CONSTRUCT, TEST, WORK ON, OR

COME INTO PHYSICAL CONTACT WITH, LIVE ELECTRONIC EQUIPMENT UNLESS YOU ARE

TRAINED OR OTHERWISE QUALIFIED TO DO SO.

- NEVER REMOVE A PROTECTIVE COVER FROM ELECTRONIC

EQUIPMENT UNLESS YOU ARE TRAINED OR OTHERWISE QUALIFIED TO DO SO, BECAUSE

LETHAL MAINS AND HIGHER VOLTAGES ARE PRESENT INSIDE. ANY PERSONAL CONTACT THAT WILL CREATE A

CIRCUIT IS SUFFICIENT FOR ELECTRICITY TO CONDUCT. DEATH IS PERMANENT.

- Extra care should be taken with circuit designs

using the B+ voltages listed in this guide.

- Safety is of extreme importance not only to

yourself the constructor, but also to other persons who may come into

contact with your creation - particularly little children.

- Live wiring should be fully insulated to

prevent electrocution of yourself and/or users.

- Tubes for use at B+ voltages over 450v DC

require sockets made from materials that can withstand high voltages.

Inferior materials may cause flashover or arcing, leading to burning,

short-circuits and/or tube damage.

- Many tube types require a top cap plate

connection and such tubes must be carefully mounted to minimise wire

length, proximity to other components and risk of accidental contact.

Insulated caps are recommended. Do not solder directly to tube caps. Do

not touch cap leads or terminals.

·

Most vacuum tubes

are glass encased devices that have been evacuated of air – i.e. they

contain a vacuum atmosphere. If dropped or impacted they are likely to implode,

shattering glass in any direction. Handle with care and respect. Do not drop or

impact. Always pack and store in padded wrapping or the manufacturer's carton.

·

When inserting

into a tube into its socket always take care to align all the tube pins

correctly with the matching socket. Incorrectly aligned tubes may result in high

voltages being applied to low voltage circuit components or systems, and may

result in short-circuit fault currents being applied with resultant expensive

damage to tubes and equipment.

·

DO NOT grasp a hot vacuum tube –

particularly power tube and rectifiers

·

To avoid serious

and permanent tube damage when constructing an amplifier, always ensure the

grid bias voltage is present at grids 1, 2 and 3 before applying B+ high

voltages to the circuit. In this regard, cathode bias and back bias configurations

are safer and more reliable designs than fixed bias.

·

Unloaded

electrolytic capacitors can hold their full charge for a week or more. Always

ensure large HV electrolytic capacitors are fitted with suitable bleeder

resistors to automatically discharge them after the amplifier is switched off -

otherwise you may expose yourself to lethal current if you accidentally touch a

live conductor. Persons familiar with

assembling and servicing personal computers and suchlike - all of which feature

fully insulated construction - must appreciate that tube amplifiers and

ancillary equipment operate at high-voltages and, unlike computers, have

unprotected open construction that is exposed to the touch - particularly

components connected to the AC mains supply.

·

Amplifiers that

incorporate a “standby” switch still have full mains voltage and high voltages

present in the system

·

ALWAYS ensure

your amplifier and guitar are grounded via the mains earth. Making contact with

another amplifier or mains connected device that are separately grounded, such

as microphone can result in electric shock.

Now that you have been suitably warned, let us proceed together to explore the

world of vacuum tube audio.

. © NOTICE: INTELLECTUAL PROPERTY COPYRIGHT © D.R.GRIMWOOD 2002 -

ALL RIGHTS RESERVED.

Copyright in all quoted works

remains with their original owner, author and publisher, as applicable.

Please note that no warranty is

expressed or implied - see footnote notice.

Intellectual property in the

original applied engineering concepts expressed in this paper remains

exclusively with their author Dennis R. Grimwood.

The whole or part thereof of

this paper and/or the designs and design concepts expressed therein may be

reproduced for personal use - but not for commercial gain or reward without the

express written permission of the author and copyright owner.

All rights reserved.

REMEMBER - ALWAYS TAKE CARE WHEN WORKING WITH

HIGH-VOLTAGE - DEATH IS PERMANENT!!

Contact:

"electron"

Email: contact

This page is located at

http://www.oestex.com/tubes/guitaramps/8_gawiring.html

This page last modified 12 July 2023