FOR

BASS GUITAR,

SLAP BASS,

BASS FIDDLE

OR

BASS VIOLIN

A PAGE FOR PROFESSIONAL MUSICIANS, AUDIO PROFESSIONALS

OR DIY CONSTRUCTORS

WHO DESIGN, MAKE OR USE

AMPLIFIERS AND SOUND SYSTEMS FOR BASS INSTRUMENTS

INTENDED FOR LIVE ON-STAGE PERFORMANCES.

"Whatever you can do, or dream

you can do - begin it.

Boldness has genius, power and

magic in it."

Goeth

Welcome vacuum tube amplifier constructors - this page is presented for your information and guidance.

It is intended to provide helpful hints to save you inevitable pain and suffering in your quest for audio and musical excellence, and to help you find joy in your chosen pathway to musical pleasure and fulfilment !!!!

Please note the information provided is not intended for the novice constructor or musician. Basic circuit theory and construction techniques are not attempted herein because it is assumed you already know that and are competent in both.

My personal professional musical instrument playing and tube audio experience extend around fifty years, so my contribution here is based upon a solid foundation of practical application of tube electronics to musical performance.

In any event, you will soon see I am not a theorist, so whatever is said is based upon a combination of the reported experiences of others, helpful guidance from my electronic guru friends, reference to published texts from people who are considered to be reliable technical experts, electron tube manufacturers' manuals and data sheets, and my own experiments, research and experiences.

I hope it is of help to you in designing and constructing

the very best bass sound system for your needs.

© NOTICE: INTELLECTUAL PROPERTY COPYRIGHT

© D.R.GRIMWOOD 2002 - ALL RIGHTS RESERVED.

Copyright in all quoted works remains with their original owner, author and publisher, as applicable.

Please note that no warranty is expressed or implied - see footnote notice.

Intellectual property in the applied engineering concepts expressed in this paper remains exclusively with the author Dennis R. Grimwood.

The whole or part thereof of this paper and/or the designs and design concepts expressed therein may be reproduced for personal use - but not for commercial gain or reward without the express written permission of the author and copyright owner.

All rights reserved.

WARNING!!

Do not attempt to design and/or construct a vacuum tube audio amplifier unless you suitably skilled, qualified and/or experienced.

The Author makes no claim whatsoever as to the validity or accuracy or otherwise of any statement, information or opinion contained in these pages and no liability will be accepted for any error or omission of any kind whatsoever.

Proceed only at your own risk!!

No warranty of any kind is expressed or implied as to the workability or performance of designs, concepts or equipment described herein.

Never forget Murphy's Law: If

something can go wrong it will !!!!

SAFETY WARNING:

Now that you have been suitably warned, let us proceed together

to explore the world of vacuum tube audio.

INDEX:

1. INTRODUCTION:

2: THE BASS REPRODUCTION SYSTEM

STEP 2: DETERMINE HOW MUCH POWER (WATTS RMS) IS NEEDED

STEP 2: SELECT THE LOUDSPEAKER

STEP 3: DETERMINE WHAT KIND OF "SOUND" YOU WANT.

STEP 4. DETERMINE IF NEGATIVE FEEDBACK IS REQUIRED OR NOT REQUIRED.

STEP 5: DETERMINE THE OUTPUT LOAD IMPEDANCE

STEP 6: SELECT THE TUBE COMPLEMENT

STEP 7: SELECT CLASS OF OPERATION

STEP 8. DRIVER STAGE CONFIGURATION

STEP 9. CHASSIS AND COMPONENT LAYOUT AND WIRING

STEP 10: B+ OPERATING VOLTAGE

STEP 11: POWER SUPPLY

STEP 12. APPEARANCE

1. INTRODUCTION:

Throughout the history of recorded music the bass is an instrument that is there - but not there - in the musical performance.

The bass part may be performed by a bass violin, a bass guitar, a tuba, a contrabass tuba, a sousaphone, a piano, a pipe organ or an electronic organ. Other instrument variants are also possible.

The primary function of the bass is to provide a platform of depth of tone and aural balance to other instruments and/or vocalists playing further up the audio frequency range. To do this, the bass part is typically one or two octaves below the other instruments or vocals.

Popular perception of this elementary "background" or "ancillary" musical function often leads to the the Bass Player being regarded as the least important musician in the band lineup - because the usual role of the Bass is to support whatever is happening further up the musical register throughout a performance.

Except in jazz music, the bass part is subtle and generally in the background. The bass part is typically not a "tune", but a series of harmonies with the tune played by others.

It is rare in popular mainstream recorded music to hear a bass solo. It is even more rare to hear a dazzling virtuoso performance from the bass line.

However, regardless of the number of other instruments present, or the complexity of the music, or arrangement, or orchestration, the Bass Player is required to match it - but in such a way as to not disturb the delicate balance of harmonies created.

Consider the band or orchestra as being a see-saw, with the bass on one side of the pivot and all of the other instruments on the other side. Balanced aural loudness is critical.

Consequently the role of the Bass Player is extremely important - albeit subtle.

Mostly the bass part is simply "just there" with no accentuation over other instruments - but its presence is known.

When listening to a musical performance, most people would not be overtly conscious of the bass line, yet without it they would become immediately aware of its absence.

Imagine the mighty work - Bach's "Toccata and Fugue in D Minor" - without a bass line !!!!

Its absence is profound. To demonstrate this point, turn the bass tone control on the stereo to the off position and listen to the effect upon the music. Music without bass is typically lifeless and dull.

In the case of classical music it is usual for the bass line to be written down by the composer and faithfully followed by the musician, however in the case of popular music it requires an ability from the Bass Player to compose in real time "on the fly" - that is, to devise a bass line that is always in harmony with whatever else is happening in the creative performance. This is particularly true for live performances, where it is expected that the bass player will not read music whilst playing.

Another vital role of the Bass Player is to work in harmony with the drums to create a rythm section. The choice of playing style of the Drummer affects the decisions of the Bass Player in his or her creativity - because these two instruments interact. It is essential they work together for common purpose.

It follows that to be a successful Bass Player, one has to contribute in a meaningful way that is constructively inter-active with others. This requires a high standard of playing ability, timing, accentuation, accurate sound reproduction and, most importantly in a large venue, adequate amplification to attain relative loudness and balance with other instruments.

At this point it is pertinent to differentiate between recorded and

live performances.

Recorded Performances

In the case of recorded performances, since the 1920's when electric recording was introduced, the bass violin was successfully recorded in classical, orchestral and popular music.

This is simply because the bass violin is an easy instrument to record. With gut strings it does not exhibit strong harmonics so presents a simple waveshape in a frequency range easily recordable and replayable with low quality equipment. Even when harmonics are absent due to limitations in recording or playback, the bass violin still sounds like a bass violin.

However challenges remained in the home reproduction from records. Early tube audio systems were deficient in bass, primarily because of low-powered single ended output stages, poor quality output transformers and small loudspeakers in open backed cabinets.

The recording characteristic for 78 rpm records typically had a more or less flat bass response - after suitable equalisation that varied from one recording to the next. Because the recorded bass was accentuated and treble attenuated, "boomy" bass was the norm for open backed mantel and console radios and radiograms of that era.

Audio system tone would be described as "mellow" or "pleasing".

However, from the early 1950's, to reduce surface noise and enable a lesser groove amplitude to extend playing time, vynil EP and LP recordings generally incorporated RIAA, NARTB or NAB bass attenuation (-20db @ 20 Hz) and treble boost (+20 db @ 20 kHz) (a completely different approach to 78 rpm recording characteristic).

The RIAA equalisation characteristic is shown below:

During the 1950's, due to improvements in playback technologies, high-end audio hi-fi systems were able to reproduce bass very well, but mainstream mantle radios, console radios and radiograms were still relatively poor. The 12 inch loudspeaker was still regarded as a "large" speaker and most home systems used only 8 or 10 inch drivers.

Console style tube radiograms usually offered a maximum of about 10 to 20 watts of audio power, thus limiting the power available to the bass spectrum. It was common for "quality" radiograms to reproduce AM radio in a superior quality sound than that from the inbuilt record player - so there was still some way to go in technological improvement.

Throughout the period from the 50's on, it was the case that 45 rpm records commonly had a 6 db bass boost at about 50 Hz to compensate for bass attenuation from small speakers in mantel radios and portable record players. Consequently 45 rpm records play back with a different tonal balance to their 33 LP equivalents.

It was not until the 1970's, with the introduction of higher powered and lower real cost transistor based audio systems with full-frequency modular components, that reasonable bass became available in the home. Sterophonic recordings required two discreete channels for playback so the sound stage improved dramatically - generally across the full width of the home listening room. Stero playback generally improves bass response and presence over monophonic. 12 and 15 inch drivers, commonly configured in two or three way systems with midrange and tweeter, became available at affordable cost.

Advances in recording equipment and techniques and staging "fashion" meant that the electric bass guitar gradually displaced the bass violin as the most recorded bass instrument in popular music.

Recording studio equalisation of the master tracks was modified to take advantage of the improved performance of stereo systems and bass became a permanent feature of modern recorded music.

More recently, enter 5 and 7 channel "surround sound" home theatre systems with powered sub-woofer. These enable massive bass power to be reproduced in the home, at a level completely disproportionate to whatever was originally performed. The high-powered car stereo, pumping out up to 1,000 watts per channel, also enables over the top bass response.

Nowadays, with 5 string basses and electronic black box effects, the lower register extends down to around 30 Hz - not really a problem for hi-fi playback systems (particularly those incorporating a sub-woofer unit) but very impracticable for high-powered on-stage live performances.

An important difference between recording and playback is that recording is performed internally within electronic devices or equipment. Once the performance is captured on a recording, it is not usually subjected to external forces or influences, such as venue acoustics, microphony or extraneous magnetic fields.

In the case of bass guitars, unshielded amplifier components can readily pick up induced magnetic fields when the instrument is physically located near the amplifier or a loudspeaker - resulting in hum or microphony or instability.

Finally, digital recordings may be manipulated manually or with software,

to produce a myriad of variations upon the original recording. However

a live performance is as-is.

Live Performances

The second consideration is for LIVE performances. Here the situation is very different.

Notwithstanding its "warmth" of tone and commanding presence, a single bass violin has a limited audible sound level and is therefore limited as the to size of venue it can service without amplification. It is also a physically large and fragile instrument so is not quite convenient to lug around to live venues.

Once the point is reached where amplification is required for live performance, the electric bass guitar becomes the favoured instrument. It is smaller, lighter and easier to play than its bass violin counterpart - but with suitable amplification, can produce a similar bass musical effect.

Of course the bass violin can also be similarly amplified, but that option is not popular for a variety of reasons.

It is also true for live performance that the power required to reproduce bass is proportional to the power produced by the other instruments present.

Given that a typical guitar amplifier will deliver about 60 to 120 watts rms and that for effective tonal balance the audible bass power level needs to be about twice that, we have a need for a bass amplifier and loudspeaker system capable of producing at least 120 to 240 watts rms of power at 40 Hz.

In modern terms, with transistor amplifiers available that can easily deliver several thousand watts of power it would not seem to be a problem to achieve this.

However, life is not that simple.

Since the invention of the vacuum tube, LIVE electronic reproduction of bass from a musical instrument has always been a challenge for musicians, audio designers and constructors - and remains so to this day.

Even electronic organs present their fair share of challenges in reproducing the lower frequency register, so have much in common with bass amplifiers.

Over the years, various approaches have been made to adapt hi-fi technologies to electronic instrument amplification, but it is clear from practical experience and theoretical analysis, that requirements for musical instrument amplification are very different to those required for hi-fi reproduction of recorded music.

"HIGH-FIDELITY" is a term that literally means "TRUE FAITHFULNESS" - to the original. Obviously that is not necessarily an objective for musical instrument amplification and reproduction, because what we are after is that elusive "sound" that creates the particular AUDIBLE musical effect we want.

What happens to the sound quality and characteristics within the reproductive system is not of concern to the player, because it is what we actually hear that matters.

This principle is most aptly demonstrated by the "electronic keyboard" - formerly known as the "electronic organ" - where the sound reproduced is created completely artificially. The only human involvement is to depress a key or press a button !!!!

Conversely, if we know the cause and effect relationships that create and manipulate the sound within the system, we can design a system that will do what we want. That is of course the methodology used by electronic organ designers, sound processors, effects pedals and suchlike

For just on one hundred years, and particularly the eighty odd years since the advent of electric recording, countless researchers and engineers have endeavoured to attain that elusive standard of performance described as "High-Fidelity".

If we review audio amplifier circuit designs from an audio engineering perspective we can see much commonality between them, but most might be described as "variations on a theme".

In fact, many amplifiers have attained their superior performance simply by taking a proven design, tweaking it (optimising circuit values) and using the very best components available at the time of manufacture. That approach is still pursued today by both commercial designers and enthusiasts alike.

If we then look at the evolution of musical instrument amplifiers, we see the same "follow-the-leader" approach at work - in this case "the leader" being the big names in commercial musical instrument amplification.

This paper takes a fresh look at some of the important elements essential to designing and constructing a vacuum tube based audio amplifier intended to reproduce BASS.

Some of the concepts can be easily adapted to existing designs, often with very minor component or voltage changes to those chosen for an existing circuit.

1.1 IMPORTANT REMINDER

The professional Audio Engineer designing for a commercial application must consider design elements and factors such as performance, construction and safety specifications and standards; tube types, characteristics and availability; component availability; continuity of supply; component cost; component quality; corporate vendor/supplier policies and preferences; corporate design policies; fashion ideologies that control appearance, shapes and finishes; component and complete device colour, machine tooling constraints; sheetmetal suppliers and materials; labour costs and assembly times; packaging and delivery requirements and costs; market/buyer preferences or trends; warranties and guarantees; after-sales service; and brand-reputation etc.

In recent years, many countries have introduced consumer protection laws that require a product to be what it is claimed to be. Consequently, all of the designer, manufacturer and retailer must consider the validity of performance claims when viewed from a statutory compliance perspective.

All of these considerations and more impose constraints upon the professional designer when approaching the design of high-fidelity and professional audio amplification equipment for commercial sale.

However the home constructor has no such constraints

!!

In our quest to attain our required "sound":-

We are blessed with more or less total freedom from all or any of the above.

We can take an existing commercial BASS amplifier and modify it, optimise it, tweak it, or do anything else we want.

We can use new, used, second-hand, salvaged, hand-me-down, or recycled components.

We are not usually constrained by original component price or cost.

We can use non-ideal, oversized or approximated components, or components that would not normally be used in such a device.

We can compromise.

We are not locked into printed-circuits and can use point-to-point wiring with confidence.

We are free to use any design we want.

We are free to have any layout we choose.

We are free to instal extra shielding wherever we want.

We are free to modify the design without having to be concerned about guarantees, warranties or product.

We can use recycled industrial, military or broadcast quality components.

We can use any tube type or mix of tube types

we want.

WE CAN EXPERIMENT ACCORDING TO OUR OWN IDEAS AND PREFERENCES!!!!

WE DO NOT HAVE TO COMPLY WITH THE CONSTRAINTS OF THE ESTABLISHED CONSERVATIVE PARADIGMS IN DESIGN OR CONSTRUCTION

WE CAN REACH BEYOND THE COPY-CAT SCHOOL OF DESIGN.

WE CAN INNOVATE!!!!

But please, before you abandon all of the hard-won knowledge developed over a century of tube audio design and application, do follow the essential core design rules set out in STEP 9 below: "CHASSIS AND COMPONENT LAYOUT AND WIRING" - ignore them at your own peril.

1.2 A NOTE FOR THE UN-INITIATED

Here are some basic ground rules:

Electricity normally behaves like a fluid. Hence when we observe the behavioural characteristics of water, we can see much relevance with electric current flow.

Electricity is a force. Hence it can have all manner of forms - not just regular AC (Alternating Current) or DC (Direct Current).

Electricity will flow when there is a pressure difference between the two ends of a conductor or a circuit.

Electricity will not flow unless there is a "circuit". A circuit can be created by hard-wiring - or by electro-static, inductive or electro-magnetic coupling through the air.

A "circuit" can be created by adjoining components, wires or even through the air. Never assume that because a hard-wired circuit is not evident, high-frequency AC current or electromagnetic forces cannot be present to influence circuit behaviour.

Generally speaking, the greater the current through a conductor the greater the extent of the electro-magnetic field around it.

Generally speaking, the longer a wire the greater the risk of electro-magnetic interference or coupling.

Electricity is "lazy" - It will ALWAYS try to find the shortest path. This attribute creates problems with devices and wiring in high-voltage and/or high-current circuits. In the context of vacuum tube amplifiers, "high-voltage" means anything above about 450 VDC. Above that, life becomes more and more difficult as all manner of unexpected phenomena occur in the amplifier.

Electricity flow can be controlled electrically, electronically, electro-magnetically, electro-statically or mechanically.

Power Out = Power In minus Losses. This works like a garden hose.

What comes out = what goes in less friction in the pipe.

.

In an amplifier, AC power out = AC power in minus conversions losses

from AC to DC then DC back to AC, multiplied by device efficiency.

2. THE BASS REPRODUCTION SYSTEM

Unlike the situation in hi-fi systems, where each discrete modular component - eg turntable, CD player, tape deck, radio tuner, pre-amp, power amplifier and loudspeaker etc - is usually selected for individual characteristics independent to those of the other components in the system, for BASS reproduction we need to look at a closer compatibility.

This is because in a hi-fi system, each component will typically have performance characteristics that exceed our needs or hearing capabilities. Inter-dependence or interference between modular components is not usually an issue.

On the other hand, in a live music BASS system, it is likely that each component will be struggling to meet our needs.

The primary reason for this is that whatever we do will be done at continuous HIGH-POWER - a situation not usually experienced in hi-fi listening.

One example is in frequency response specs. Long ago the commercial audio engineering fraternity decided that Frequency Response should be measured at one watt rms - not exactly a difficult standard.

They also decided that Intermodulation Distortion should be measured using just two frequencies - neither of which have much relevance to BASS amplifiers because a bass amplifier will normally be reproducing only one frequency at any time.

Finally, standard lab tests are always performed using resistive loads (which present a constant load impedance to the amplifier) at frequencies that are above the lower bass register - ie below 120 Hz - where we need maximum performance.

All of these standards were based upon the characteristic of vacuum tube amplifiers which, in any given amplifier, cause distortion to increase proportionately with power output. So quoting performance at full power output was usually avoided.

Note: Solid state amplifier manufacturers now quote amazing performance specs for their amplifiers at full power output. What they do not tell you is that over-driving the amplifier beyond its limint causes total collapse of the waveform into square-waving and often self-destruction of the amplifier through overheating of the power stages. Destruction of the loudspeakers is also a common event. The performance specs also do not tell us what the amplifier sounds like.

Now a glance at the impedance characteristics of any electrodynamic bass speaker (ie standard magnet/voice coil/cone driver unit) shows a huge impedance change up and down in the region of most use in bass.

Consequently, published hi-fi amplifier performance figures are effectively useless to tell us what we need to know for BASS reproduction.

This remains true also for current generation solid state amplifiers, where rated power output and distortion performance are usually expressed at a specified load impedance - eg 4 or 8 ohms. This has been measured of course with a purely resistive load at a specified standard frequency. However connect to a variable load like a loudspeaker and a different result will be seen.

Note: Solid state amplifier manufacturers now quote power output at a specific load impedance but often do not tell us that under-loading the amplifier - ie presenting a load impedance below the specified value - can also cause self-destruction.

On the other hand, except for the occasional power output rating, tube bass guitar amplifier manufacturers have never published performance figures at all.

So our starting point for the BASS amplifier is

a no-man's land of electronic theory, design and application.

THE VACUUM TUBE

The vacuum tube is to an amplifier as the carburettor is to a motor vehicle engine.

If there is no input regulating device, an engine will simply run at full RPM and power output - usually to self-destruction, so the carburettor serves to regulate fuel/air gas mixture and flow into the engine as a means of regulating engine power output.

By means of controlling carburettor operation, the driver determines the speed at which the engine operates - to produce power for transmission through the drive train to the driving wheels.

Similarly, the vacuum tube is an electro-mechanical electronic regulating device that uses a small input effort to produce a comparatively large output power.

Just as we would not claim the butterfly valve in a carburettor produces the engine power output we would not also claim the input signal voltage to a vacuum tube produces the amplifier power output.

Importantly, the vacuum tube, like the carburettor neither produces power nor consumes it (excepting for heating requirements and efficiency losses).

In considering BASS audio amplifier design principles, it is first vital to understand the vacuum tube serves two fundamental purposes or functions:

First Primary Function:

The first primary function of the vacuum tube is to electronically regulate the Direct Current (DC) flowing through it in such manner that it varies in direct proportion to the applied ALTERNATING CURRENT (AC) signal voltage. This is effected by injecting the AC signal voltage into Grid #1 of the vacuum tube. (Other Grids can be used but Grid #1 is the most common configuration).

It is the variable Direct Current flowing in this circuit that, when applied into a LOAD, produces the Alternating Current OUTPUT.

Thus the Alternating Current OUTPUT applied into a LOAD produces the useable output from the amplifier.

To simplify our understanding, we could regard the Direct Current circuit as the SOURCE of power - or INPUT POWER, and the Alternating Current circuit as the LOAD - or OUTPUT POWER.

Hence the vacuum tube could may be classed as a TRANSDUCER because it converts energy from one form - ie Direct Current (DC) to Alternating Current (AC). On the other hand, the complete Amplifier is not, because it uses an AC input to produce an AC output.

The resultant Alternating Current output means that a single vacuum tube provides a common current path for BOTH Direct Current and Alternating Current circuits.

In the case of the DC circuit, that portion of the current path between Plate and Cathode terminals of the vacuum tube, is used to REGULATE the DIRECT CURRENT flow in the whole circuit under constant supply voltage conditions by means of the Control Grid (Grid #1). A negative DC voltage (Grid Bias) is applied to it so that it will present a negatively charged element that controls the current flow to the desired level by interfering - in a deliberately controlled manner - with the ability of the Plate to attract electrons from the Cathode.

Because the vacuum tube has negligible internal DC resistance or AC

impedance (see tube rectifier characteristics for typical values) and it

is a current path in the circuit supplied by the Power Supply, it is essential

to insert a LOAD into the circuit to limit total current to acceptable

limits - otherwise the tube would behave as a low-resistance metallic conductor.

Second Primary Function:

The second primary function of the vacuum tube is to provide a return current path for the power supply source input power - which is in DIRECT CURRENT form.

Without a return path no current will flow in the power source circuit. That is to say, current can only flow in the circuit when the vacuum tube conducts.

This is demonstrated by the fact that if the power supply voltage is applied to the Cathode and Plate terminals of a cold vacuum tube, current will not flow. However if a fixed resistor - having the same resistance value as that specified for the design value of AC load impedance for the particular power output vacuum tube(s) - is inserted into the circuit in series with the vacuum tube and the tube terminals bridged with a wire conductor, then DC current will flow to a value determined by the resistor.

In the case of a Plate loaded output transformer configuration, the output AC circuit load also is shared with the DC circuit - ie is common to both circuits. This is achieved by installing the LOAD in series with the Tube Plate and Cathode terminals.

The value of the DC power so consumed by the circuit will be equivalent to the maximum AC power output plus circuit losses.

Fundamental to BASS amplifier design is the principle that maximum power output of an amplifier is limited to the "prospective power" of the power supply - ie the maximum power (Volts x Amperes) the power supply can deliver in any instant of time into its load.

Actual maximum signal power output (including any distorted component) cannot exceed the "prospective power" capability less circuit losses. Circuit losses are always very significant, even at at audio frequencies, ranging from about 23% minimum to about 70% of power supply DC input power.

Thus what is of most significance to us is that assuming a constant value of load in the circuit, Actual amplifier power output is regulated by the vacuum tubes in the circuit - not by its load.

Another important concept to understand is that electron flow in vacuum power tubes does not operate in quite the same way as in the electroplating process. In that process using Direct Current, particles of a metal material are transferred from the Cathode to the solution, thence to the Anode - which is the article being electroplated. The Cathode metal is consumed by the process and eventually there is none left.

However in a vacuum tube this process does not occur - ie during normal tube operation significant amounts of Cathode material do not deposit onto the Plate. This tells us that the electron flow in a vacuum tube may be nothing more than a static stream of conductive particles that assemble in the tube to bridge the Cathode to the Anode (Plate).

Hence, the performance and "sound" of an audio amplifier should be far more dependent upon circuit design and componentry than what goes on in the vacuum tube itself.

Practical experience though tells us differently and there is provable difference in sound between different tube types.

Electricity:

Finally, the audio amplifier is not quite the static solid object that it appears to be.

Electricity, as a force, is fluid.

That means it neither does not, nor cannot, anchor itself to a solid object. It can only move from one solid object to another (eg a set of contacts) or move within or through a solid object to another (eg a wire or cable or X-Rays), or through a fluid such as air (electric arc) or water (electric current), or through a vacuum (eg an electron beam such as in CRT) or space (eg microwaves or light).

So long as there is a potential difference between two points in a circuit, current will flow. However, for current to flow, there must ALWAYS be a CIRCUIT.

Thus if electric current passes through a conductor, there MUST be a return path back to the source so that the circuit is complete and equilibrium is restored.

This is why no current flows when a positive and negative polarity voltage is available from a pair of terminals but there is no load connected. Or why an electric lamp does not light up until the power switch is turned "on" to create a circuit.

In audio amplifier applications, it is the LOAD that normally forms the return current path.

However, the return path MUST be electrically separate to the forward

path - otherwise a short-circuit will result.

Kirschhoff's Current Law

The algebraic sum of currents entering and

leaving any point in a circuit must equal zero - ie no matter how many

paths

into and out of a single point in a circuit,

all the current leaving that point must equal the current arriving at that

point.

Thus the extremely important principle to note is that in an audio amplifier, the current returning to the source does not have to be the same current that left it.

In other words, current can be drawn from an alternative source, or sources, to complete the circuit such that current back equals current forward.

Having said this, in the case of an audio amplifier, we find a whole collection of individual circuits within it - many of which SHARE current paths.

Hence the designer must pay close attention to what is transpiring separately in each individual circuit - as well as the inter-action and inter-dependence between individual circuits and sets of individual circuits.

Note that Kirschhoff's Law applies separately to BOTH AC and DC circuits - therefore each AC or DC circuit should be analysed independently to all other circuits, as well as interactively with all other circuits in the amplifier.

It is this phenomenon of inter-action and inter-dependence between circuits that causes much angst in audio amplifier design, because not a great deal of attention has traditionally been given it.

Example 1: the concept of negative loop feedback from loudspeaker to input is a good example of how to ruin an otherwise fine set of circuits, because the loop feedback circuit bridges several individual circuits and by so doing, creates a time-delayed interaction and inter-dependence that is otherwise not there.

Example 2: the alternating current and direct current circuits that exist about each vacuum tubes are separate but also together. Each is dependent, inter-dependent and inter-active with the other.

Example 3: the B+ bus usually provides a common source of power to all stages of the amplifier, resulting in a situation where the current in each stage affects the voltage available to each other stage.

Example 4: losses in the output transformer and power transformer must be offset, otherwise their circuits cannot be in equilibrium. But because what comes out is not the same as what goes in, the designer should pause a moment and think about what effect mixing the output with the input might have on performance, stability and capability.

So the message to the audiophile designer is that to effectively design and construct a high-quality audio amplifier using electron tubes, pay close attention to what is happening at each and every point in the circuit and how each individual circuit might interact with every other circuit in the amplifier.

Each individual circuit about each individual stage in the amplifier should be carefully designed to optimise performance for that stage.

STEP 1: DETERMINE HOW MUCH POWER (WATTS RMS) IS NEEDED

User needs for final electric power output determine the core requirements for critical components such as tube type, output transformer, power transformer, chassis size, ventilation and gross weight.

These in turn, determine needs for B+ voltage and current, grid bias voltages, rectifier and electrolytic capacitor voltage ratings etc.

Hence, a very apt starting point is to determine power needs.

It is assumed you will be using loudspeakers - which are transducers used to convert alternating current electrical energy into acoustic, audio or sound pressure energy. Loudspeakers are notoriously inefficient and fragile devices and great care should be taken in their selection, mounting, installation and operation.

Generally speaking, listening to recorded music in an average room at a comfortable level requires only about one watt RMS - which is surprisingly loud with an 85-90 db SPL efficiency loudspeaker - even much more louder with 100 db SPL efficiency units.

Note however that an SPL on its own does not convey the volume of air being pumped. The SPL rating is a measure of "loudness" determined at 1 watt electrical input (amplifier output). Power used to be measured with a single frequency rms signal, but nowadays all kinds of rating changing techniques are used by loudspeaker manufacturers to rate power input - eg music power, white noise, pink noise, peak power, programme power, etc etc - all expressed in "watts".

We may reasonably then ask the question "what is a watt"?

Or, "when is a watt not a watt"?

To provide for the minimum full dynamic range of recorded music - ie 20 db - a total power rating of 100 Watts RMS will be a reasonable target to enable transients to be reproduced without too much audible distortion above normal listening requirements.

In this age of digital recording, musicians have found it necessary to resort to effects to produce saleable product, hence it is common nowadays for CD's to incorporate extreme levels of low frequencies of all kinds of waveforms, to produce that "thumping" brain-deadening sound so beloved of today's teenie-boppers.

Unfortunately this means that to attain realistic sound reproduction free from audible distortion, a 100 W RMS amplifier and a 100 W RMS loudspeaker system (50 W RMS per channel - stereo) is mandatory. This equates to 150 watts EIA, 200 watt peak or up to 1600 watts PMPO.

Of course a lesser level of power may be usefully utilised but transients will be cut-off or truncated, with a corresponding loss of realism.

A more detailed explanation of this requirement is provided by Dave O'Brien, formerly from McIntosh Laboratories, in his description of his "Spectral Fidelity Test for Intermodulation Distortion" (IMD). IMD is what causes the sound to become "fuzzy" at high volumes.

See also an interesting overview at http://www.axiomaudio.com/archives/power.html

Note that recording technologies have always been far ahead of playback technologies. Examples of just how good recording technologies and standards have been in the past are easily heard by listening to recordings made way back in the 1940's and 1950's, or even earlier in some cases. (Some of my CD's include original recordings that go back to 1910). When transcribed to CD format and cleaned up, these recordings contain signal information not previously heard with conventional playback equipment. The information was always there on the original tape, but just not accessible. However thanks to advances in audio recording and transcription technologies, now it is.

Except as otherwise determined from the following information about loudspeaker performance, when used in a typical domestic home situation, an amplifier/loudspeaker combination of less than 100 W RMS will simply produce overload distortion in all of its forms on transients and/or intermodulation distortion on steady state heavy programme material such as sustained pipe organ music.

However this distortion may not be heard in practice because the amplifier may actually simply chop the top off the transient peaks, in which case everything else will sound just fine up to that power output level where the whole system collapses through severe overload. What will be heard is a modified sound, but the modification may not be discernible to all but the most critical listener.

On this basis, a 10 watts RMS per channel TUBE stereo will still do the job well.

In contrast, a 25 watts per channel RMS SOLID STATE amplifier will be needed to produce the same loudness through the same loudspeakers. Why? Who knows, but that's the way it is.

For those who prefer their music through headphones, then the above does not apply. Brain destroying loudness is attainable through headphones at very low power outputs - ie less than one watt.

Pop music tends to be based upon short transients comprising sound forms to which the ear is unfamiliar, so it is easy for the average listener to tolerate very high levels of distortion - simply because the listener does not know the sound is distorting. Not so with familiar programme material such as classical music, popular programme material from yesteryear, or live recordings of musical instruments and voice well known to the listener.

However, a rational approach to hi-fi is that if you cannot hear

the distortion then don't worry about it!!

STEP 1.1: LIVE STAGE PERFORMANCE

Commercial bass amp systems for live stage work come in wide range of options.

From the humble 20 watt practice amp to the gargantuan systems used for large venues, the bass musician has a myriad of choices available.

Large PA systems are beyond the scope of DIY so are not described here.

Consider the band or orchestra as being a see-saw, with the bass on one side of the audio frequency pivot and all of the other instruments on the other side. Balanced aural loudness is critical.

A general rule of thumb is that the bass amp must have a rated power rating of at least twice but preferably four times the rated power output of the lead guitar amp.

That means at least 120 watts rms to 240 watts rms for the typical bass guitar amp.

However that is a practical minimum requirement to get by.

Above that level a tube amplifier is likely to be too heavy to cart around so the option is to either go to solid state (250-500 watts rms minimum) or to a DI (direct injection) feed into a large PA system.

Of course the size of the venue, crowd numbers (people soak up power) and indoor v outdoor conditions (outdoor offers no reflected sound) affect the minimum power needs.

IMPORTANT: It is of no use connecting a powerful amplifier to small loudspeakers or inefficient loudspeakers or connecting with undersized cables where losses will be high (potentially up to 50% or more)

For bass the more speakers the better, the bigger the speakers the better and the more cabinets the better. In my experience 12 inch drivers sound better than 10 inch, 15 inch drivers sound better than 12 inch, 18 inch drivers sound better than 15 inch. Then the more cabinets the higher the acoustic efficiency.

Consider a guitar amp driving a 4 x 12 inch quad box.

Noting the human ear is more efficient at higher frequencies, the bass guitar will need an equivalent to 8 to 16 x 12 cabinet(s) to deliver the same effective loudness.

See also Section 2.5 below re loudspeaker response and SPL efficiency.

One of the curious aspects of modern band sound systems is that the typical band will have two fifteen inch PA speakers set high on pedestals for voice, two to eight 12 inch loudspeakers for guitar, one or two fifteen inch loudspeakers for keyboards, and sometimes two eighteen inch subs for drums - but just ONE fifteen inch loudspeaker for bass guitar !!

The resultant tonal balance is obvious.

Worse, in the case of solid state bass amps, many commercial models have the LF boost frequency for BOTH tone control and graphic EQ set to 100 Hz - a full one and one half octaves above bottom E.

Others use 50 Hz.

Both options produce muddy bass and require the

bassist to use a pick to deliver an acceptable sound.

Fortunately some amps can be easily modified to correct this by changing the value of the boost capacitors.

The ONLY way to achieve a solid bass sound is to use tone controls and graphic EQ having a LF range to 32 Hz. Odf course this is essential for a 5 string bass where the bottom open string is around 30 Hz.

Food for thought !!

BUYER BEWARE.

STEP 2: SELECT THE LOUDSPEAKER

Next we look at the loudspeaker.

In traditional hi-fi systems, the bass loudspeaker (woofer) intended to reproduce down to about 30 Hz requires a large enclosure of at least 8 cubic feet volume, made from heavy timber and suitably padded internally with damping material.

However this is just not practicable for the professional musician because the box is too big and bulky, too heavy and will not readily fit into our motor vehicle or onto a stage.

Large, heavy enclosures are not likely to fit comfortably onto a standard venue stage after the other musicians have taken their share of available space. large, heavy enclosures can also present a safety hazard if their centre of gravity is too high, or their height to base dimensions ratio is out of proportion (read tall, narrow or thin enclosures)

Graphic equalisers and tone controls are usually used to compensate for bass rolloff in the lower register - if at all

What we need for the professional BASS musician is a small enclosure having a high power handling capacity in the lower register.

Most importantly it must have an even frequency response so that as each note is played moving up or down the musical scale, the sound loudness will be constant.

That is a big ask.

However, all is not lost because buried in the annals of textbooks and papers, is a wealth of information to help us in our quest to build our ideal BASS system.

2.1 SPL Rating

One useful indicator of power needs is the loudspeaker's SPL (sound pressure level) rating. This rating is determined by measuring sound pressure (acoustic) energy under standard defined conditions - usually at 1 metre from the radiating surface with an electrical input power of 1 watt RMS at 400 Hz (cps).

The SPL rating enables a quick reliable comparison to be made between different choices of loudspeaker. For example a speaker having an SPL of 87 db will require TWICE as much electrical input power (RMS Watts) as a similar size loudspeaker having an SPL of 90 db to reproduce the same sound pressure energy level (ie "loudness") in the listening room.

In other words a 10W amplifier/90 db loudspeaker combination will sound just as loud as a 20W amplifier/87 db loudspeaker combination!!! Now there is some food for thought!!

If you can afford electrically efficient loudspeakers like JBL, Altec, Electrovoice, or Eminence, having a sensitivity of 105 db SPL or more, then amplifier power needs will be hugely less - unless you like very loud music!! Believe it or not, such a loudspeaker will need only 1/63 rd the power of that needed to drive an 87 db efficient loudspeaker. That is, your JBL, Altec, Electrovoice, or Eminence, will be effectively 63 times more powerful with the same amplifier!!

Another way of saying it is that a 105 db loudspeaker driven by a 1 watt amplifier will be just as loud as an 87 db loudspeaker driven by a 63 watt amplifier. Time to throw away those old inefficient drivers!!

For further details of the relationship between power and decibels please refer to the Decibel Chart provided.

A word of warning though - increased loudspeaker efficiency means higher output levels for background hum, noise and hiss. More attention will be needed to the amplifier's design if an acceptable result is sought. Ultimately there will be a trade-off between the competing needs. There is some practical justification then in using a low-cost amplifier to drive a low cost loudspeaker!!

When comparing SPL ratings ensure they have been measured using the same method. Some manufacturers quote SPL ratings at full rated output, which will obviously look better than the SPL produced from 1 watt at 1 metre.

NOTE: Although some specific brands of loudspeakers have been mentioned above as being (relatively) "high efficiency", not all of the models produced by these manufacturers are in that category.

SPL ratings for specific brands and types of loudspeakers vary widely

so it is recommended that the manufacturer's catalogue data sheet be studied

before forming conclusions.

2.2 Power Levels

It is wise to limit power output to a level that the loudspeakers can withstand comfortably, noting that loudspeaker power ratings are generally set at 400 Hz and assume the loudspeaker is installed in a properly designed enclosure that provides adequate cone loading and damping to limit system resonance and prevent cone overshoot.

As a rule of thumb, it is a wise precaution to halve the loudspeaker manufacturer's ratings, particularly if they are published as "peak" watts.

Music power, IHMF and PMP etc. ratings should be appropriately derated to RMS equivalent.

Remember, our SPL rating is measured at 400 cps. The actual frequency response over the full frequency range - particularly in the lower register - needs to be evaluated.

It has been observed that some manufacturers slightly exaggerate the power ratings of their loudspeakers - computer speakers are a current example - eg 1200 W from a 4" loudspeaker - so look for documented verification or test reports of quoted or claimed ratings.

Always compare speaker ratings on RMS rated power handling capacity. RMS is an internationally recognised unit of measurement and provides a standard way of rating and comparing.

On the other hand, the commonly used rating of Peak Power has different meanings in different places. It can be anywhere from 1.414 x RMS to 2 x RMS.

PMPO, or Peak Music Power Output, means the instantaneous power the unit can handle. It essentially relates to the current the unit can handle for a very short interval of time before it fuses or the speaker mechanically self-destructs. PMPO is totally useless and meaningless rating for BASS guitars.

The short-time current a conductor can carry during a short-circuit - such that the conductor heats to a predetermined temperature during the duration of the short-circuit, is defined as I squared x T (current squared x time = a constant). The value of the constant is irrelevant - except to determine time.

The International Standard time for determining short-circuit ratings (which require the conductor to remain intact and not suffer visible damage) is ONE second, so for practical purposes the temperature rise of a conductor is determined by the square of the current - which is also the formula for determining power.

We can thus say that the power handling capacity of a loudspeaker (or any wire based device such as a transformer) is directly proportional to the electrical current in - up to its maximum capability, when the conductor will fuse (in a loudspeaker this is the voice coil winding)

PMPO ratings simply take an RMS value and divide it into a very short time interval.

If we use that one second nominal time as a basis for determining a PMPO rating, then for a 10 watt RMS rated loudspeaker at 400 Hz (which is the standard rating frequency), we can calculate a PMPO rating for a time interval of one half of an RMS cycle (1/800th of a second for a 400 Hz signal) by the formula:

1 second multiplied by 800 = 800 x 10 watts = 8000 Watts

This is how 10 watts increases to 8000 watts!!

Obviously the rating will vary dramatically with frequency.

If we increase the frequency to 1,000 Hz the PMPO will increase to 20,000 watts.

Remember ancient Australian saying: "BULLSHIT BAFFLES BRAINS" !!

2.3 Loudspeaker Design and Construction

Many modern loudspeakers have huge magnets and rock hard cones made from heavy plastic, metal or carbon fibre materials.

Unfortunately none of this indicates efficiency and it may well be that a loudspeaker that looks rugged and chunky with huge magnet actually has a low SPL performance resulting in a severe efficiency loss matching the lower price tag.

Often it will be observed that in loudspeakers up to 15 inches in diameter, those having small magnets and paper cones actually outperform those with large magnets and plasticised carbon fibre cones - particularly in the lower bass region. This is because the heavy cone requires more power to drive it. More power input means more electrical current through the voice-coil. More current means larger diameter wire. Larger diameter wire is heavier and produces a lower ampere/turns ratio in the magnetic field. Heavier wire means more mass to shift. More mass to shift requires a stronger magnetic field. A stronger magnetic field requires a larger, stronger magnet. Because there are physical and cost limitations on all of these parameters, the usual approach is to simply use larger wire, which translates into less electrical efficiency in the electromotive energy available to drive the cone.

Another relevant design feature with modern high-excursion cone drivers is that when the cone is driven to its extremity, the voice coil must still be within the magnetic field of the pole piece to electro-magnetically drive and/or control cone movement. It is obvious that the more the cone travels in and out, the longer the voice coil must be, which means there will be fewer turns of wire actually in the magnetic field of the driver at any instant of time. This translates into lower efficiency - unless design techniques are incorporated to maintain the electro-mechanical efficiency of the transducer.

So our modern inefficient 100 W RMS loudspeaker may need 100 W to drive it - but not to actually deliver more sound pressure output than the 20 W loudspeaker of yesteryear.

Cone suspension systems vary markedly but, as a rule of thumb, modern rubber surround suspensions used in sub-woofers and car (automobile) audio speakers are not as reliable as the traditional "accordian" suspension. Cellular foam rubber suspensions tend to literally fall apart after a relatively short period of time - particularly if exposed to sunlight.

When selecting a loudspeaker, check to ensure the cone can move reasonably freely - but not "floppy" - and the spider suspension (usually yellow treated fabric around the voice coil at the back of the cone) is of large diameter and capable of free travel.

The spider should sit flat to position the voice coil centrally in its magnetic field.

It will be observed by the very critical listener that paper-coned loudspeaker sound qualities vary throughout the seasons. In summer, when cones dry out, they tend to give brighter, cleaner sound, and sound louder. But in winter, or wet weather, the moisture content in the cone increases, making it heavier and therefore less sensitive to transient peaks, producing a 'duller" sound.

Bass response will tend to improve slightly and resonance reduce from a heavier cone. This feature is incorporated into heavy duty professional bass speakers, which have heavy cones, heavy voice coil wire and large magnets to maintain efficiency.

Note however that a well designed loudspeaker of modest power rating - eg 25-30 W RMS - does not need a large diameter voice coil or large magnet to be an effective transducer.

For high fidelity reproduction, it is far better to have a light cone move little than a heavy cone move a lot - the further the cone travels the less linear the sound reproduction will be.

It follows that for a given level of power output, a large diameter

loudspeaker will be more linear than a small diameter loudspeaker.

2.4 Loudspeaker Frequency Response

The BASS guitar has a useable frequency range of about 3 octaves.

Bottom E is at about 40 Hz and top E at the G string is about 160 Hz.

Specifically, when the instrument is tuned to Middle C pitch of 256 Hz:

Bottom E is at 40 Hz

Top G is at 192 Hz

The harmonics of G occur at approximately 384 (2nd), 576 (3rd), 768 (4th), 960 (5th), 1152 (6th), 1344 (7th), 1536 (8th), 1728 (9th), 1920 (10th) Hz.

So allowing for a top fundamental frequency of say 200 Hz and harmonics of 2,000 Hz, we do not need midrange or tweeters for bass.

A good quality cone speaker will do the job well.

However there is more to bass than fundamental frequencies, so some degree of midrange is desirable for colouration.

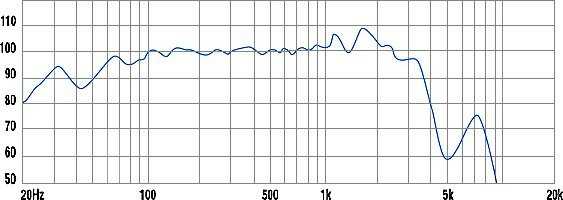

The modern trend to multiple 10 inch drivers is a case in pont, where

solid bottom end is traded off for loudness and light weight. The typical

10 inch drivers illustrated below show response at 40 Hz is -10 db down

on response at 100 Hz - a difficult task to offset by equalisation.

2.5 Frequency Response and Power Response

The POWER response of a loudspeaker system is critical for bass because a frequency response of -0 db at 40 Hz in one unit compared with a frequency response of -20 db at 40 Hz in another (compared to sound output at 400 cps), equates to an ELECTRICAL POWER difference of 100 times to attain the same LOUDNESS at that resonant frequency.

That will be impossible to attain at useful power levels because the loudspeaker will not be able to handle that much power.

Similarly, a frequency response difference of 3 db equates to a need for twice the electrical power to attain the same "loudness" - refer Decibel Chart for power ratios.

So a better (ie 'flatter") bass frequency response curve means cost-free power output. It also means more natural sound where individual notes across the musical scale are reproduced with more equal loudness.

SYSTEM 1:

An example of this phenomenon is shown in the following typical frequency response graph for a high-quality low-frequency reproducer - ie "Woofer" - SYSTEM - ie Woofer loudspeaker mounted in an enclosure.

IMPORTANT NOTE: These graphs do not show the frequency response of the loudspeaker by itself, and include enclosure resonances and enclosure design impact upon loudspeaker performance - which is what the listener hears in any case.

Note the average SPL of 100 db across most of the usable frequency range,

indicates unusually efficient performance over a very flat response curve

- by any measure this is a "top of the range" LF Woofer driver unit.

Loudspeaker System 1

In this case, the loudspeaker is mounted in a medium sized vented enclosure, resulting in two peaks at 33 Hz and 66 Hz about the natural resonance of about 43 Hz.

Note: Although HF response rapidly falls away above 3,500 Hz, the frequency response needs described above indicate this loudspeaker is suitable for bass guitar.

The important feature to note with this enclosure configuration is that even when using a very high-quality transducer offering an average SPL of 100 db, the efficiency at system resonance (43 Hz) drops to 87 db - a reduction of 13 db on the average. Although this may appear to be an alarming performance, it is very typical of vented-enclosure loudspeaker systems.

However, because of its uneven response in the LF region, this system would not be suitable for bass guitar applications - unless suitably equalised - but may be very satisfactory on hi-fi playback.

On the other hand, if the lower register is equalised to flat response, supported by adequate amplifier power, then this system shows remarkable flatness across the entire bass guitar range of fundamentals and harmonics.

The slight increase in SPL in the mid-range is also of great benefit in speech applications.

It is also noteworthy to comment that the enclosure used for the above test is relatively large by volume. Typical small volume vented enclosures will demonstrate substantially higher peaks above and below the natural resonance - see paper on Loudspeaker Enclosures design.

Patchy LF response is definitely noticeable to the musician and should

be avoided where practicable.

SYSTEM 2:

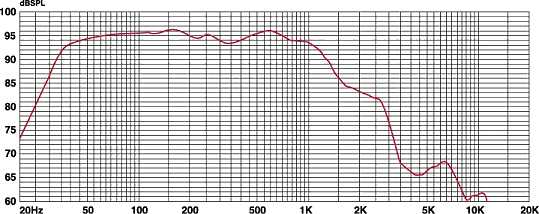

When mounted in an infinite baffle enclosure (ie sealed box) of generous proportions, or in a wall, the response curve will change to something like the following:

Loudspeaker System 2

Note: This is not the same driver unit as per the above Loudspeaker System 1 but the effect is well demonstrated.

In this case, the low-frequency response falls away rather evenly, with no peaks or troughs in the response curve - AND - the efficiency at 40 Hz (bottom note on a bass guitar or double bass violin) drops away to only 93 db - less than half the reduction in efficiency with a vented enclosure.

Unfortunately the enclosure must be large - ie around 20 cubic feet minimum - to avoid increasing the resonant frequency of the system. For example, an enclosure of 5 to 10 cubic feet volume should increase the system resonance to about 80 to 100 Hz, causing the flat section of the response curve to start to roll-off at about 100 Hz instead of the 60-70 Hz shown.

Provided the amplifier can deliver the required power, such a system can sound quite strong at the bottom end when suitable bass boosting is used - eg tone control or graphic equaliser.

It is also of interest to note the average "flat" section of the frequency

response is about 3 db down on the first graph - System 1 - this system

thus requiring twice the input driving power for the same loudness.

SYSTEM 3:

This system is included to demonstrate the different low-frequency and high-frequency roll-off characteristics to System 2.

Loudspeaker System 3

The curve of Loudspeaker System 2 shows the SPL at 40 Hz is 95 db - which is more or less the same in practice.

However the HF response of System 3 rolls off rapidly from 1,000 Hz - which will produce bass lacking in harmonics and therefore definition.

Consequently, the loudspeaker of System 2 is the better choice for bass.

But in a two or three way hi-fi system Loudspeaker System 3 will deliver a more interesting mid-range and a brighter bass tone.

However bass guitar is not hi-fi

.

.

2.6 Tweeters

It is customary in two or three way loudspeaker systems to rate the whole system and not the individual components. Hence a tweeter from a 100 W RMS hi-fi system may actually only have a 10-20 W RMS rating on its own (within the restricted frequency response of the tweeter), because in typical music the power output is substantially more in the lower register than in the HF range.

It is common to see lower priced drivers rated in "Music Power" in an attempt to match low and high frequency power ratings when processing a "music" signal.

The tweeter and/or midrange unit in fact may have an even lower power rating if it is supplied through a system crossover network, which typically soak up 50% of power input (-3 db insertion loss).

In the case of the three examples above, for an even full-range frequency response, the Tweeter driver would need to have an efficiency matching the Woofer driver unit. In all three cases illustrated, the Tweeter will need to be of very high quality - ie SPL 95-100 db - to match the Woofer performance.

WARNING: In the case of guitar amplication, Tweeters cannot be successfully used in the same way as in hi-fi systems. The guitar pumps out high frequency signal at much the same power level as midrange or low frequency signals. This means that Tweeters must have a similar power rating as woofer units in the same system.

PIEZO tweeters usually have very high power ratings but exhibit very patchy frequency response characteristics, rendering them unsuited for high quality systems.

One way around this is to use twin-cone speakers, however these are generally intended for PA applications and not made with power ratings high enough for BASS. Of course multiple twin-cone units may be practically viable for some users.

There are however exceptions designed for musical instrument applications.

The P Audio 10 inch models HP10W and HP10T illustrate the difference between identical professional musical instrument loudspeakers with and without a "whizzer" tweeter cone. This loudspeaker spec. sheet has been chosen as an example because it directly compares identical designs, which are typical of this class of loudspeaker.

Note the improvement in HF performance above 3,000 Hz in the case of the twin cone unit HP10T. This characteristic defines the advantage of a "whizzer" cone, which enables the loudspeaker to be driven at full power across all frequencies within its range.

IMHO twin-cone speakers are the very best option in lead/rythm guitar applications, where strong harmonics are desirable. In the case of BASS guitar, twin-cone loudspeakers can be used satisfactorily but are not necessary - unless strong harmonics are required by the musician.

Note: As with all cone tweeters, Whizzer" cones are directional, so

as the listener moves away from the frontal axis the SPL reduces, however

in the case of bass reproduction this is not likely to be an issue. However

if the amplifier is to be used as a backup for other instruments or voice,

then twin cone loudspeakers are a good investment.

.

.

2.7 Multiple Loudspeakers

Multiple loudspeakers - preferably of identical design and construction (although satisfactory performance can be obtained with dissimilar but tonally compatible units) - connected in series or parallel as needed - are a very efficient means of adding more power handling capability. It is usually cheaper to add an extra loudspeaker than to double amplifier power. Conversely it is usually cheaper to add an extra low-cost loudspeaker to double power handling capacity than to instal a single high cost higher performing unit. Do the sums!!

There is a cutoff point though - at about 100 W RMS continuous, where the available options for loudspeakers disappears very rapidly.

Few manufacturers make loudspeakers capable of handling both the electrical and physical stressors created at this power level. Usually they come in giant sizes - ie 18 and 24 inch drivers, which are beyond the bounds of practicality for most home users. However a true 100 W RMS can easily be handled continuously by four 12 inch drivers, mounted in a single large enclosure, or in multiple enclosures.

15 inch drivers are of course superior to 12 inch for bass.

Generally speaking, the bigger the better.

Serious consideration must be given to the loudspeaker behaviour at the power level intended to be reproduced. The validity (genuineness) of manufacturer's ratings needs to be carefully researched because it is too late to discover that a manufacturer has exaggerated ratings after the loudspeakers have been purchased and installed.

A little headroom can save an expensive loudspeaker from self-destruction

resulting from electrical or physical damage.

.

.

2.8 Distortion

Loudspeakers are notorious for generating distortion - of many kinds - so the more headroom the better. It follows that multiple speakers will require less cone travel for a given level of acoustic energy (loudness).

Twin-cone loudspeakers incorporating a whizzer cone, tend to change their frequency response with increasing cone travel. At low power outputs the cone and voice coil are very much controlled by the magnetic circuit, but at high cone excursions the cone may over-travel, be less damped, and lose relative drive to the high frequency whizzer cone - resulting in diminished high-frequency response and increased intermodulation distortion. However twin cone loudspeakers offer simplicity of enclosure design, high power output, predictable response and are a preferred low-cost option for public address systems, guitar amplifiers, car audio and home sound systems where full-range reproduction is sought. There is no loss of power into crossover networks.

In twin cone units it is preferable for the "whizzer" cone to be of curvilinear, exponential or logarithmic curve shape - ie trumpet like form. Plain simple cones do not provide linearity in frequency response or ideal tonal properties or SPL.

Some researchers have suggested that mixing twin-cone loudspeakers with

tweeters does not work well, however it has for me so I am converted to

accepting mixed cone systems.

.

.

2.9 Cone Excursion

Remember that the more the cone excursion, the greater the cone over-travel and the greater the back EMF into the amplifier.

Cone travel is a product of its kinetic energy so basically the heavier the cone the harder it is to stop it and reverse its direction - in response to the driving signal power.

If the amplifier is configured with negative loop feedback, the higher back-EMF will cause the feedback system to work harder, which in turn will cause the tonal properties of the sound to change as the amplifier tries to correct the effects of back-EMF from the loudspeaker system.

Another feature of excessive cone travel is substantially increased intermodulation distortion - not so much of a problem for bass guitar or electronic organ, but a definite challenge for hi-fi.

A simple solution to this effect is to use multiple loudspeakers in a totally enclosed or suitably loaded enclosure. The internal air pressure dampens cone travel in both directions, resulting in substantially higher efficiency and reduced back-EMF.

Research has demonstrated that the more cones included in an array of loudspeakers, the greater the low-frequency response from the system.

Watch cone movement - in and out. All loudspeakers have finite physical limitations.

To protect loudspeakers from damage and to extend useful service life and reliability, it is better to use multiple drivers with cones travelling less than a single driver with cone travelling more.

Damping of the cone movement can be electrical via amplifier feedback

systems and acoustic via cabinet design, however since we want to pump

air at low frequencies, damping can be counterproductive.

.

.

2.10 Crossover Networks

Another design element to consider is that commonly used crossover networks soak up power so it is an essential pre-requisite to determine how much audio power will be lost in the crossover network and add that to total needs.

Commonly seen losses in crossover networks are in the region of 3 db, which is another 50% of power gone down the drain, never to be heard of again!!

Some crossover networks are worse than that.

Crossover networks also suffer roll-off at the crossover frequency - ie roll-off in both upwards and downwards responses, so there tends to be a hole or dip at the crossover frequency.

So for BASS guitar we do not want a crossover network in the loudspeaker system.

If top end is wanted, then it is better to bi-amp with an electronic

crossover up front.

.

.

2.11 Enclosures

Horn systems are significantly more acoustically efficient that direct radiator systems - in the order of 30% compared to 5% - ie up to six times more efficient. Accordingly, the amplifier drive requirements for a horn system may be significantly less. However horn systems have different "sound" or tonal qualities to direct radiator systems and that may not be acceptable to all listeners.

All loudspeaker systems require adequately damped cabinets to minimise resonance from the cabinet material and shape. This can occur at any audible frequency - not just in the bass register.

In the 1950's it was the norm for enclosures to be as large as was practicable. Totally enclosed loudspeaker enclosures (infinite baffle) require large volume for low resonance - 10-20 cubic feet volume was considered the minimum essential for resonance free solid bass response down to 30 Hz with a 12" speaker (it still is).

Dedicated audiophiles actually built enclosures having sand-filled walls to attain effective enclosure resonance damping.

Vented enclosures (with or without tunnel or passive radiator) offer substantial reduction in enclosure size but produce two resonance peaks above and below the natural loudspeaker resonant frequency, resulting in a sometimes obnoxious peaky bass response on some kinds of program material. (This is why bass guitar speaker systems tend to use a totally enclosed (infinite baffle) design for best results). But the advent of small apartments for the masses has led to demand for "bookshelf" speakers. Unfortunately bookshelfs do not reproduce sound very well. Get a real loudspeaker and a real enclosure!!

Finally, in my opinion it is wiser to spend more on the loudspeaker than the amplifier, because the loudspeaker will have greater effect on the final sound. A practical way of evaluating this statement is to check out a typical automobile radio retailer's display setup where a range of loudspeakers can be switched to connect to a common amplifier. The results are profound, and tell us a lot about how loudspeakers "colour" sound.

It also tells us that in the current global trading environment - price and performance are not directly connected.

EXTREMELY IMPORTANT: A cone loudspeaker is a simple air pump. Cone loudspeakers rely upon a tight seal between the front and rear of the cone to prevent the acoustic energy short-circuiting around the rim of the frame. The free air power handling of a loudspeaker is only a small fraction of the rated power handling capacity when properly mounted and loaded in an enclosure because the lack of acoustic loading on the cone can result in over-excursion of the cone and potential physical damage at quite lowe power levels - particularly at the resonant frequency.

In the case of bass guitar applications where

power levels and cone excursions may be high, it is desirable to seal the

metal rim of the frame to the cabinet with a sealant such as black mastic

compound - particulalry when the speaker is mounted on the front of the

baffle.

.

.

2.12 Tone

Tone controls and/or graphic equaliser are essential for a BASS guitar system.

IMPORTANT: The low frequency boost should occur at 40 Hz or less, rather than the 50 Hz popular in hi-fi systems.

If the boost frequncy is too high, the bass is likely to sound boomy or hollow. When coupled with a poor quality speaker system, the result will be hollow bass devoid of depth of tone.

STEP 3: DETERMINE WHAT KIND OF "SOUND" YOU WANT.

The "sound" or "tone" of a vacuum tube audio amplifier may be varied at will - or better put, may be customised to suit your personal tastes and hearing capabilities.

However "sound" or "tone" are subjective terms and will vary in conceptual meaning between individuals.

The old adage "one man's trash is another man's treasure" is very apt in this situation, so a person's description, or expression, of a particular sound characteristic or quality will mean something quite different to another person hearing the same sound.

Terms like "bright" tone may be "harsh" to someone else, and "smooth" or "mellow" may be "dull" to another, so avoid (if you can) prescribing tonal qualities as far as you can.

However, the basic styles of output tube configuration do have generic tonal properties that may be fairly recognised as being significantly different to each other.

The choices include:

Furthermore the tonal qualities will be vastly different for either single-ended or push-pull configurations, each of which offers unique tonal and distortion properties - see article.

Important: The "sound" or "tone" of any amplifier can be dramatically changed by replacing just one component in a circuit. So before replacing your expensive entire amplifier just replace one or two selected components.

(the trick is to figure out which ones!!)

The first place to start is the interstage coupling capacitors. Generally speaking, the larger the caps the more "deep or bassy " the tone will be and the smaller the caps the more "bright or trebly" the tone will be. However some commentators suggest excessively large coupling capacitors produce "blocking" distortion.

Other components that can be changed for improvement are the values of plate resistor, cathode resistor, grid #1 resistor (all variable + or - ) and electrolytic filter caps (generally the bigger the better).

Also for a cleaner but softer tone try removing cathode bypass capacitor to all driver stages (not power stage).

Changing any of the above components may cause instability so take care.

My policy is to ensure all Grid #1 resistors are the smallest viable value and never more than 100 k ohms. This reduces hum and noise, increases stability and enables the use of feedback free circuitry.

STEP 4. DETERMINE IF NEGATIVE FEEDBACK IS REQUIRED OR NOT REQUIRED.

Negative feedback offers advantages and disadvantages.

Negative feedback is the commercial solution to reducing hum and noise in audio equipment.

My recommendation is avoid using it - except within the output stage in the form of ultra-linear connection.

NEVER across multiple stages.

Note: Uncompensated (ie no negative feedback) pentodes and beam power tubes usually deliver significant "bass boom" at the resonant frequency of the speaker system. Unless a push-pull triode, or parallel push-pull (ie multiple pairs) tetrode or pentode, or an ultra-linear tetrode or pentode output stage is used, this boom may be intolerable.

Other techniques include using a large heavy construction fully sealed enclosure (ie infinite baffle) having heavy cabinet damping (eg carpet underlay or fibreglass insulation glued to the timber)

None of this is practicable with "bookshelf" sized

speakers so either use a triode output stage or get a transistor amp.

STEP 5: DETERMINE THE OUTPUT LOAD IMPEDANCE

This step is quite critical because it will have great effect upon performance and sound properties.

IMPORTANT NOTE:

The load impedance specified for an amplifier

is a nominal value only. Laboratory tests verifying frequency response,

distortion and power output are used with RESISTIVE loads. However in the

real world we use a loudspeaker to convert the electrical power into acoustic