electron's

OPTIMISED

ELECTRON STREAM © TECHNOLOGY

for

AUDIO

and RF MODULATOR

TRIODE,

TETRODE, PENTODE AND BEAM POWER TUBES

This website is dedicated

to the protection and preservation of tube audio technology.

Home

Page

CONSTRUCTION

AND WIRING OF

TUBE

AMPLIFIERS

This page presents examples of fastidious

design, layout, wiring and construction in tube amplifiers.

There are many, many such examples available

in the world and here is but a small selection to ponder upon.

If you have one to display please send

me a link or details to the HOME PAGE email address set out below

First - "the rules":

CHASSIS AND COMPONENT LAYOUT

AND WIRING

Review of past design practice shows us that many designers had no idea

of the principles essential to optimising chassis layout.

In a wide range amplifier, the wiring and componentry act as antennae,

to pick up stray and induced signals, such as ultra-sonics, RF, hum and

noise, from adjacent circuitry and transformers.

The basic rules for component layout and wiring are:

-

do not mount electrolytic capacitors close to tubes - the caps will dry

out and fail

-

do not mount electrolytic capacitors close to transformers - the caps may

induce hum and interference into the B+ bus

-

do not mount hot tubes near transformer windings - the windings will burn

or dry out

-

do not mount driver stage tubes near transformers or mains wiring - to

avoid induced interference or hum

-

do not mount exposed driver tubes near output tubes or rectifier tubes

- they may pick up induced signals such as RF, hum and even audio, and

trigger parasitic oscillation in the circuit

-

do not mount tubes near the edge of the chassis - they can burn the enclosure

or cabinet when the chassis is installed and operating

-

do not mount input wiring near output wiring either within a stage or across

stages - to avoid stray signal induction or oscillation

-

do not mount input terminals near speaker terminals or mains supply leads

or plugs - to prevent instability and/or interference from induced signals

-

do not mount tubes upside down without restraining devices - they can fall

out partially, with loss of one or more contact pins, or completely fall

out and break

-

do not mount tubes horizontally unless their grid wires are installed in

the vertical plane - to prevent grid wire sag when hot and thus uneven

electron flow, or internal shorts

-

always use shielded wiring for signal pathways in the early stages - to

prevent stray hum and noise pickup and induced feedback signals

-

never ground potentiometer wires to the chassis at the potentiometer -

always ground directly to the relevant cathode (through a shielded co-ax

lead)

-

always shield input tubes with discrete shields or a grounded metal enclosure

(there are currently more than 100 million mobile telephones in the world,

thousands of radio and television transmitters and significant numbers

of high-powered industrial and military transmitters, and they do generate

a significant amount of RF energy for your hi-fi amp to pick-up)

-

always mount tubes as close to each other as space will permit - to minimise

wiring length and minimising exposure to induced signals or interference

(but always leave at least a 10 mm gap between bottles for natural air

cooling - more for larger tubes having more than 25 watts plate dissipation)

-

always use short leads between connection points - to minimise wiring length

and minimising exposure to induced signals or interference

-

never connect pins on tube sockets directly together with straight or solid

or heavy wire unless there is a loop to enable each socket pin to locate

properly about its tube pin - tube pins do not bend well to match socket

misalignment, so some movement in the socket terminals is essential

-

always mount tube sockets such that the heater pins are aligned with the

direction of wiring - to minimise heater lead length

-

always twist heater wires together - to neutralise AC radiation to nearby

wiring and components (cancel-out hum signals)

-

always ground grid and cathode resistors (and bypass caps where applicable)

to the cathode pin, if grounded, or to the grounded end of the cathode

resistor. One very effective technique is to instal the resistors vertically,

straight up from the socket pins, then simply join the ends to be grounded

together (neatly). Connect them via a wire to chassis ground. This bundle

of components does not need further support as they are a strong structure

mounted directly from the tube socket. Some miniature sockets have a centre

tube spiggot for shielding the pins from each other - this should be also

grounded. The tube shield provides a useful structural support

-

where practicable, instal interstage capacitors with the outer layer connected

to the previous stage plate - to minimise hum pickup Vintage caps often

had a band printed on one end to indicate the outer layer

-

try to layout the chassis following the circuit diagram (schematic) - this

method actually works!!

-

ensure the amplifier is well ventilated - to ensure adequate cooling and

to facilitate long-term component life

-

always insulate and isolate high voltage and mains power circuitry - death

is permanent!!

-

always use an isolating transformer between the mains power source and

the rectifier and heater/filament system (to prevent electrocution)

-

always insulate and isolate high voltage capacitors - particularly large

capacitance units - they can store electrical energy for several days.

An amplifier switched off may still be hazardous or even lethal

-

always use an enclosed METAL chassis system - if necessary fit a removable

lid/cover for component access. 20 gauge galvanised steel sheet (1 mm)

thick is ideal but aluminium is more suitable for large chassis to reduce

weight. Note that it is not possible to solder components to aluminium

using tin/lead solder so all chassis joints must be tightly screwed together.

-

never use 50/50 tin/lead solder - that is for plumbers. Use only a high

quality 60 tin/40 lead solder having a cored flux. When soldering components

to prevent dry joints (imperfect metallurgical joint bond) always allow

time for the joint to thoroughly heat before removing the soldering iron.

Printed circuit board conducting strip tends to separate from the bakelite/fibreglass

base board if overheated - best to avoid them.

-

always ground or earth the chassis (to prevent electrocution). Note: the

earth side (outer shielded cover) of the input shielded lead must be grounded

to the amplifier chassis to prevent hum pickup, however modern television

receivers do not have an isolating power transformer and use a "hot" chassis

system. This means that if you connect yourself - or someone else - between

the TV chassis and ground there is a high likelihood of electrocution or

death. If connecting audio signal leads to a TV receiver or similar device

ensure there is an isolating capacitor in series with each lead - ie both

live and earthed input leads, to prevent direct connection between the

amplifier and the hot (ungrounded) source. If you are not qualified to

do this then take your system to a qualified technician - you only have

one life!!

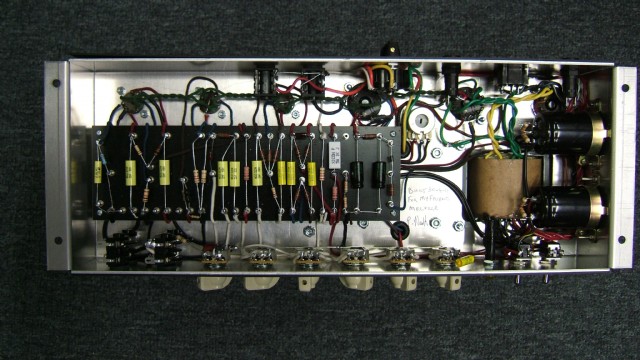

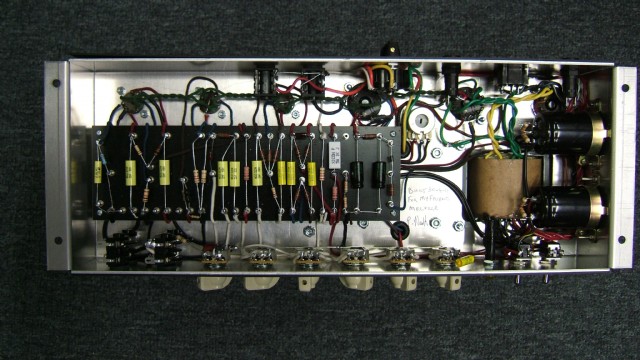

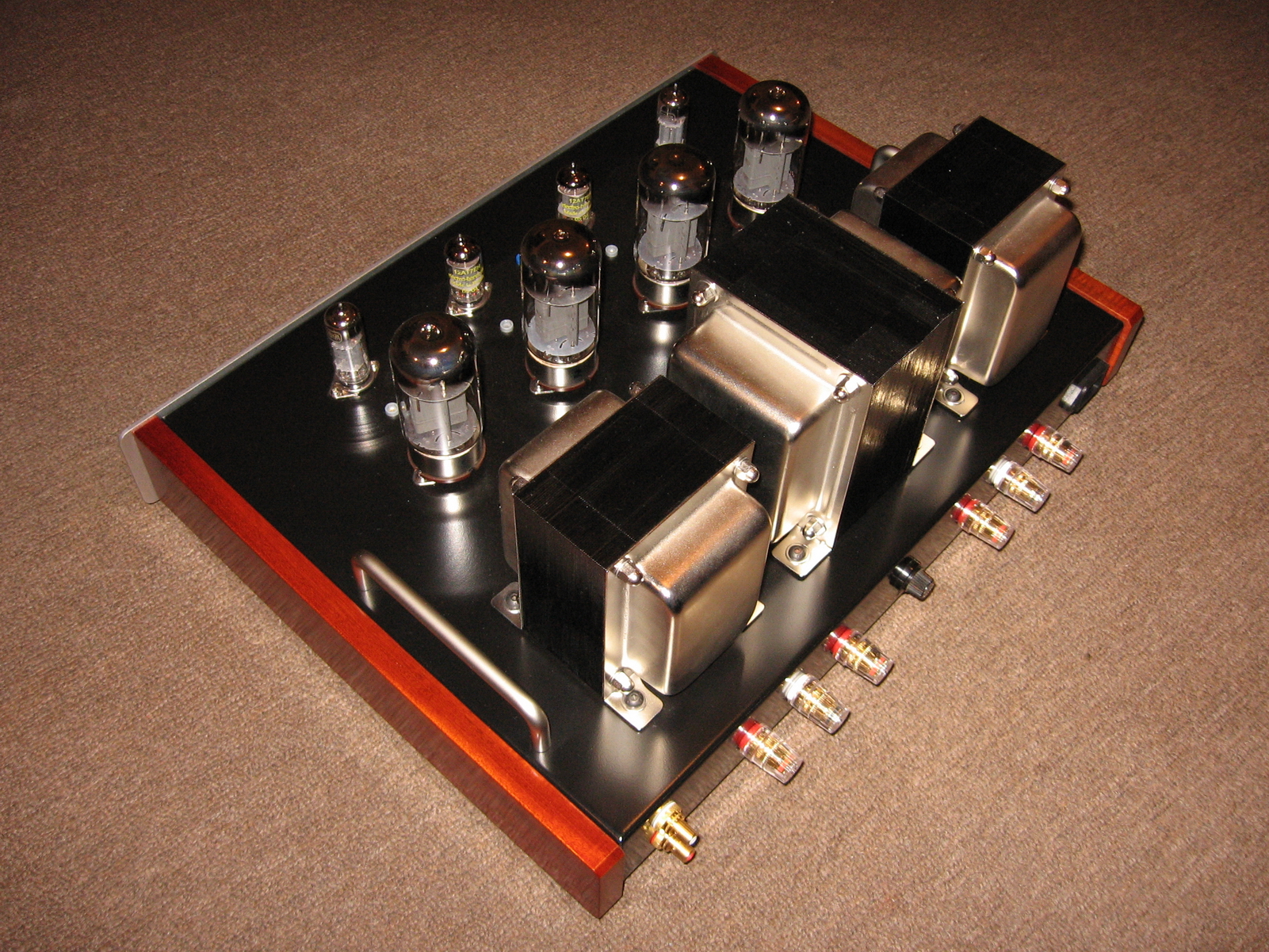

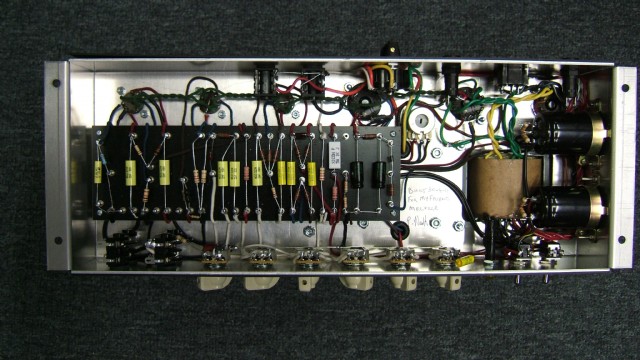

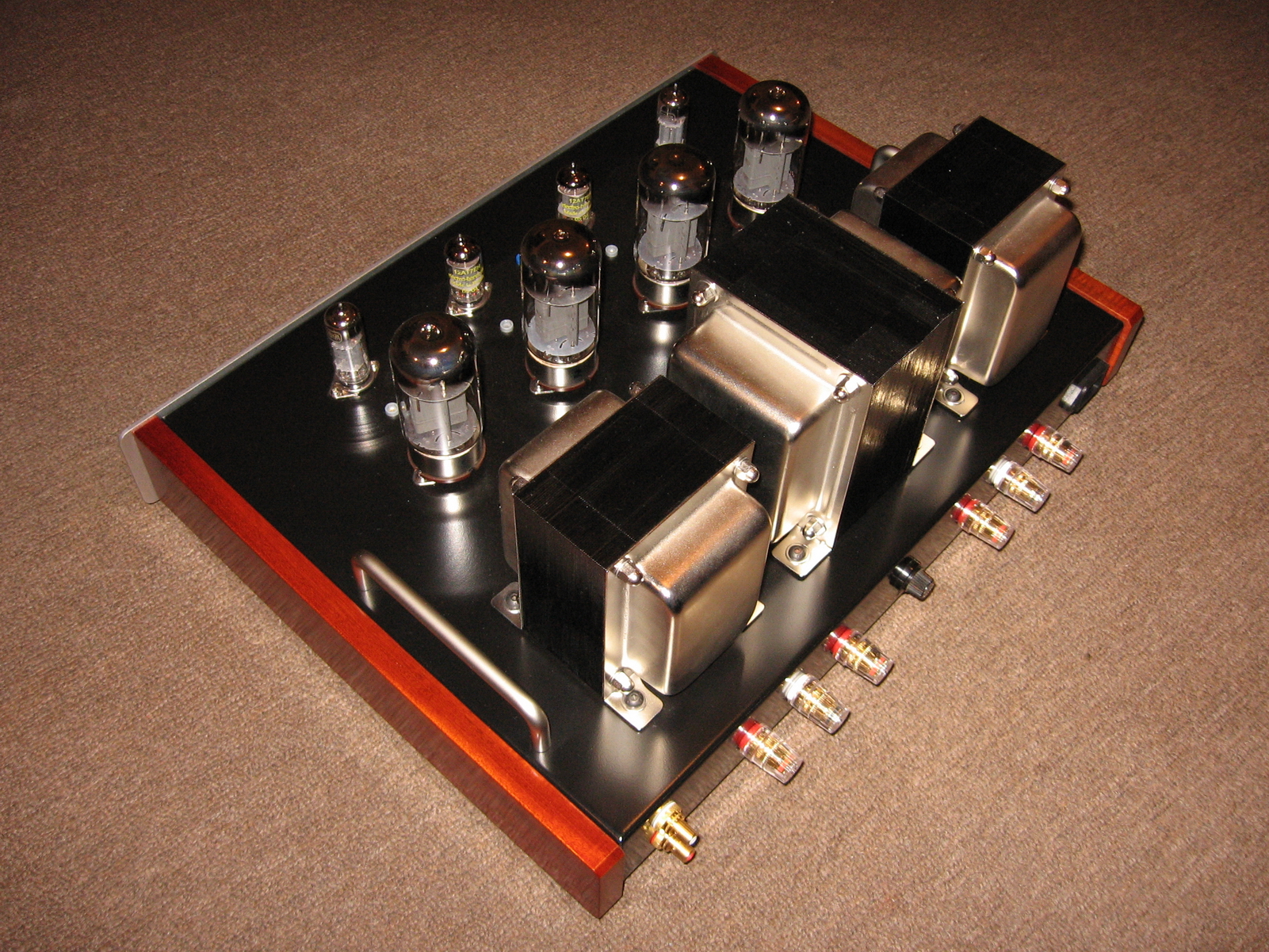

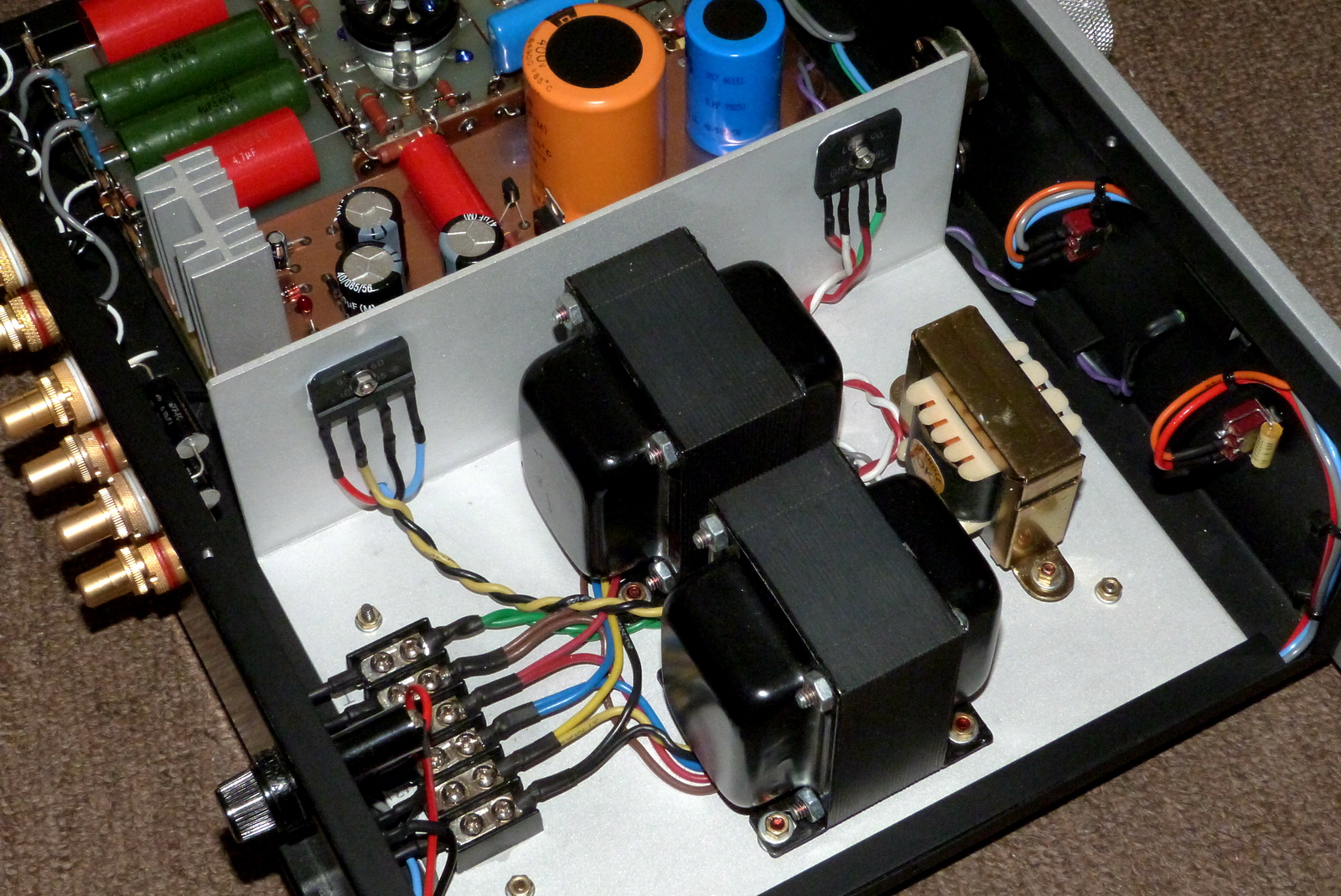

EXAMPLE 1: PN Electronics

- Australia.

Shop 3, 16 Cockburn Road, Hamilton Hill. Western Australia 6163

Website: http://www.pnelectronics.com.au/

email: info@pnelectronics.com.au

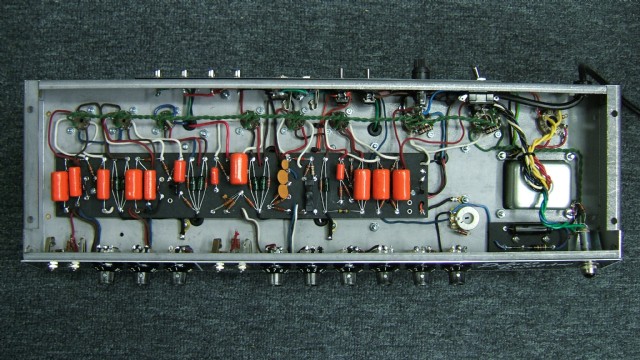

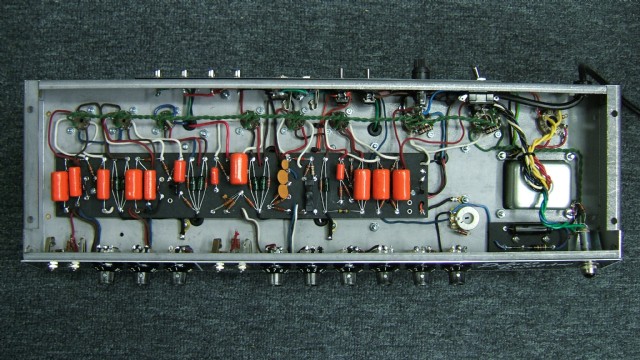

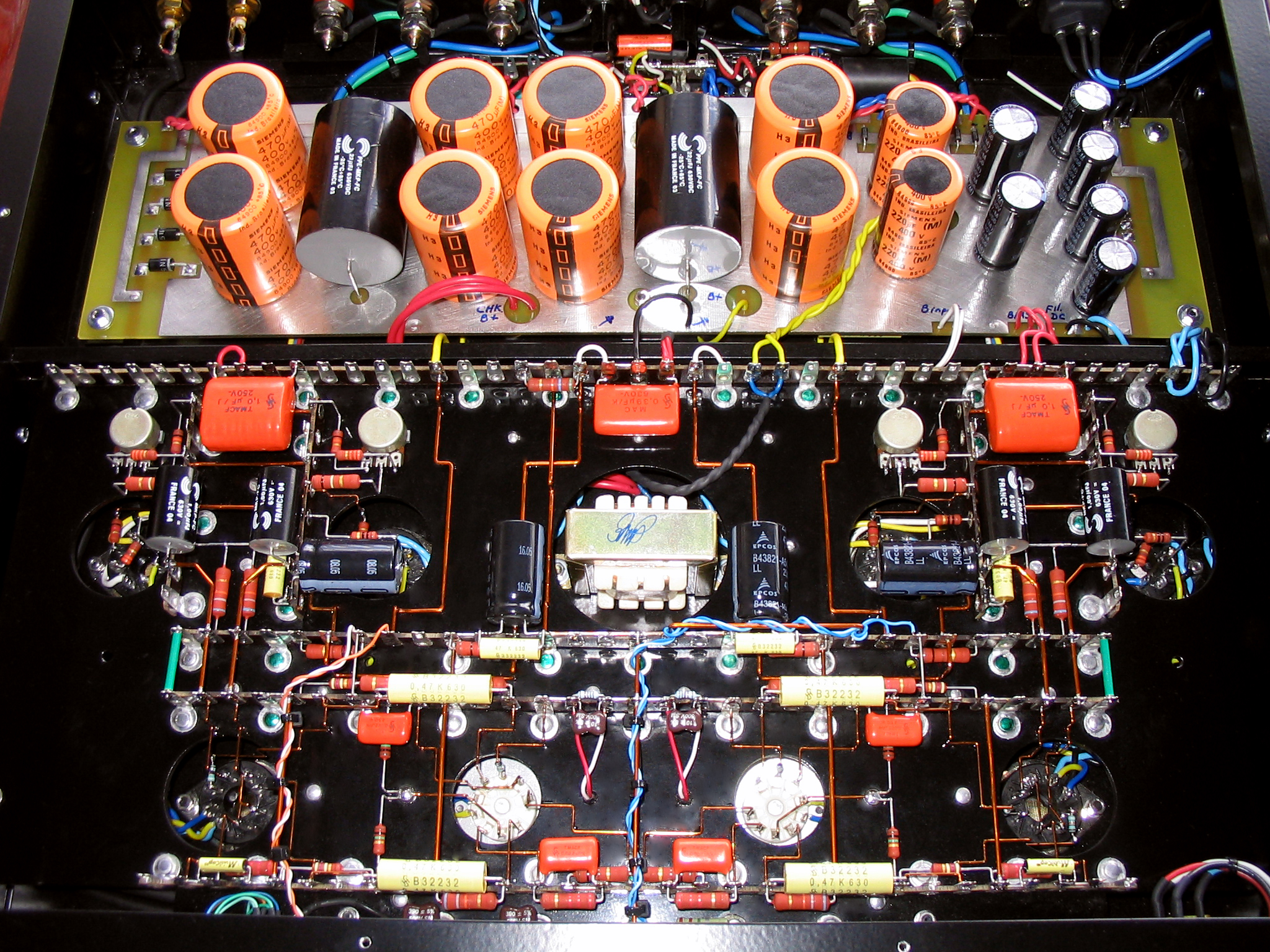

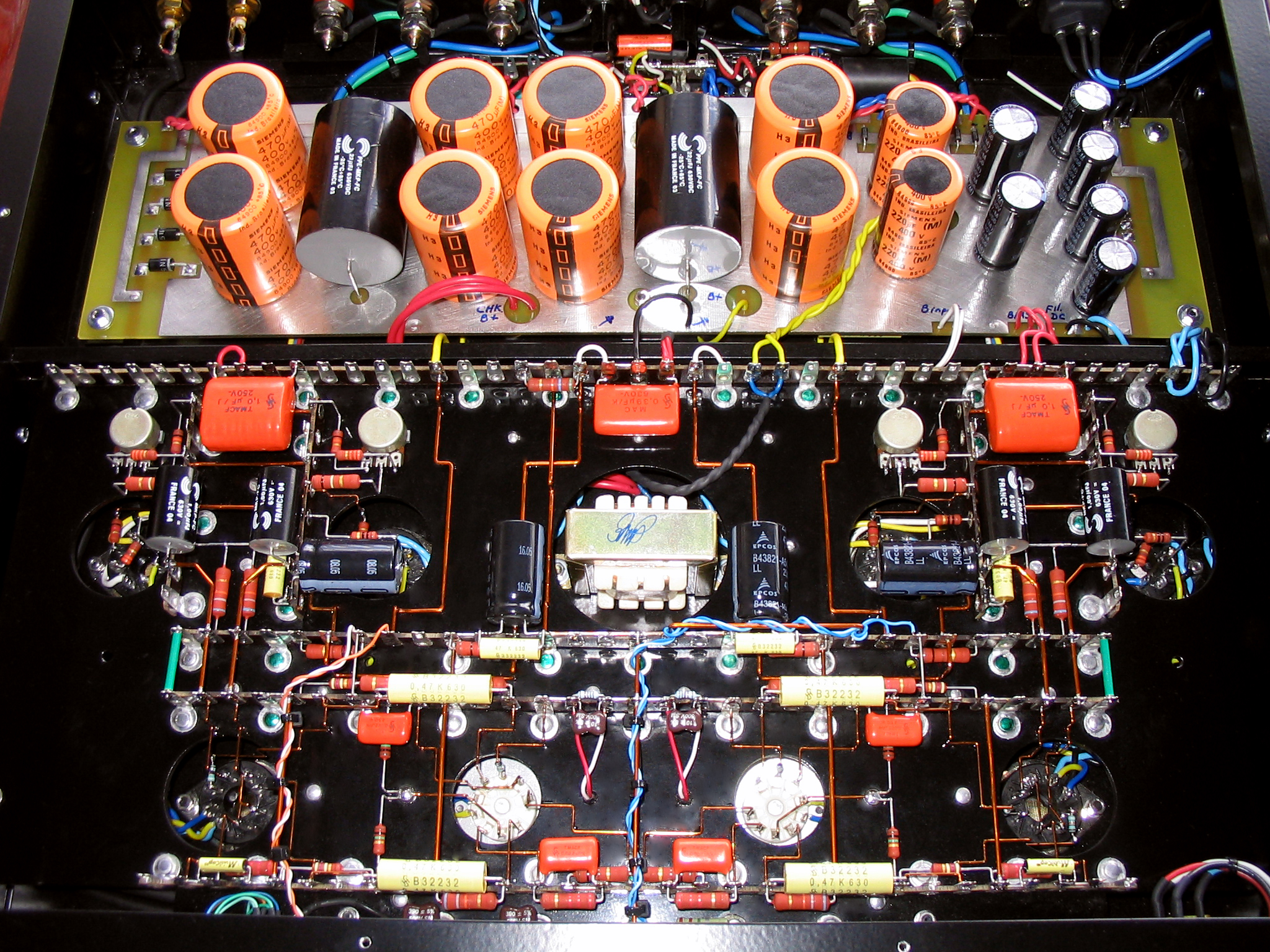

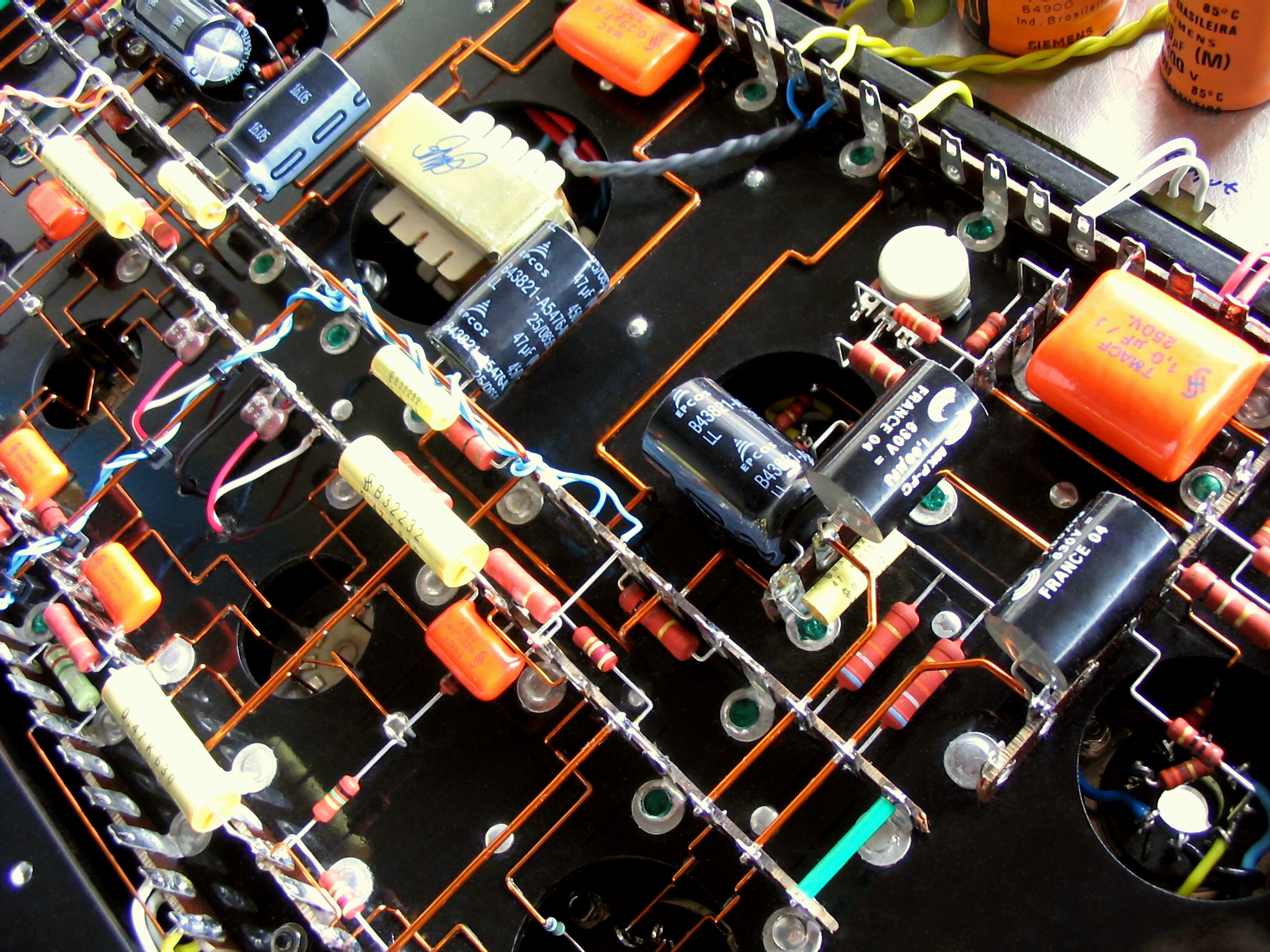

EXAMPLE 2: VTR POWER AMPLIFIERS

- Brazil

Central Brazil, Belo Horizonte City, Minas Gerais State

website:

email: rwellerson@hotmail.com

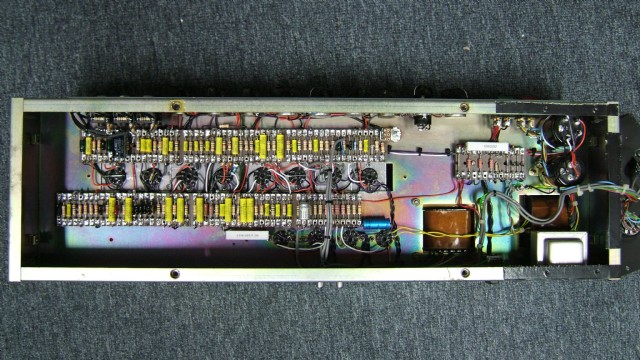

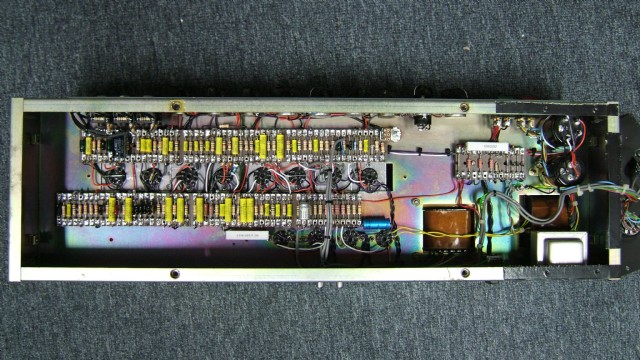

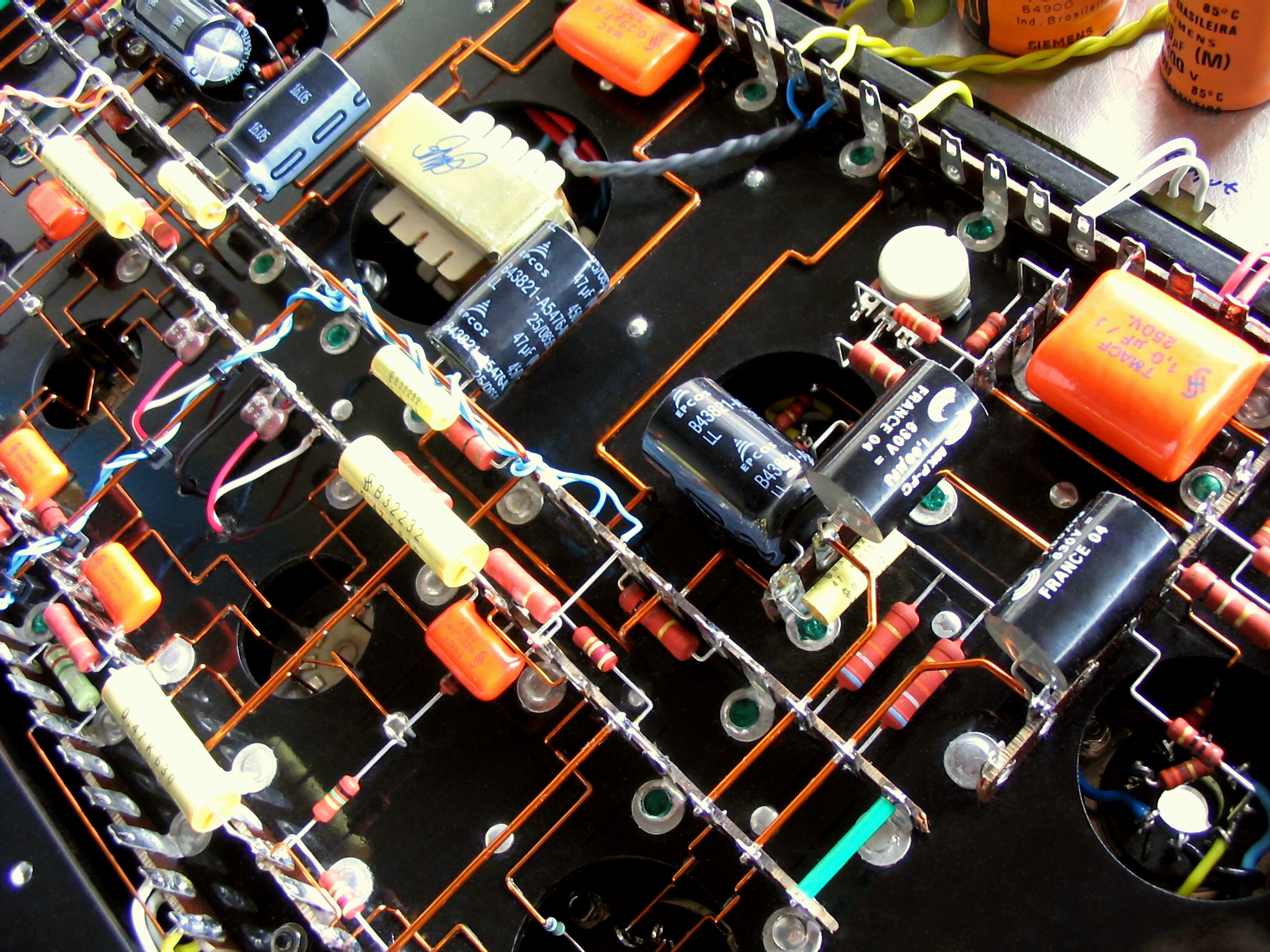

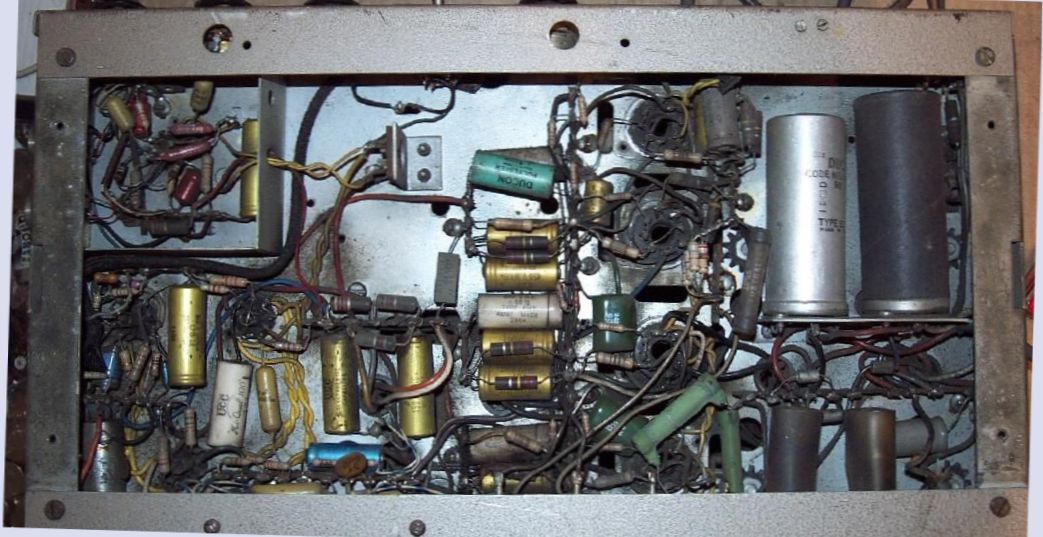

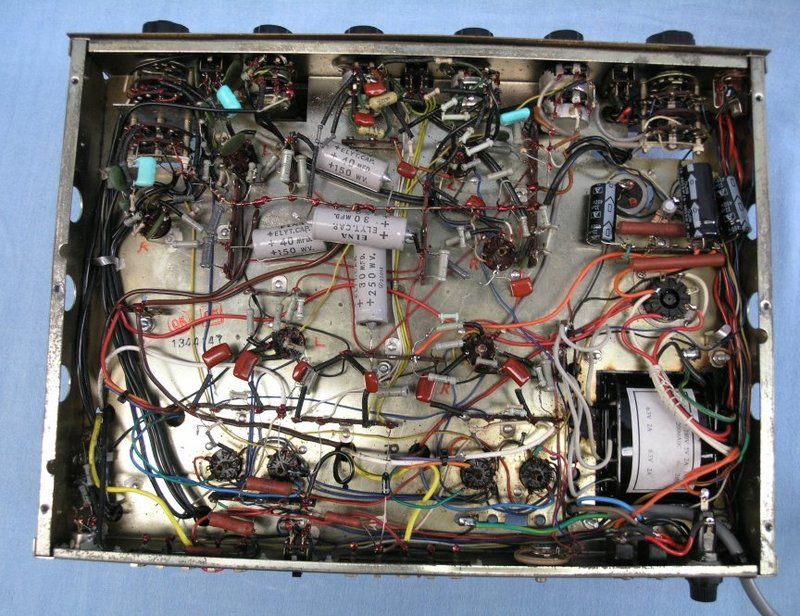

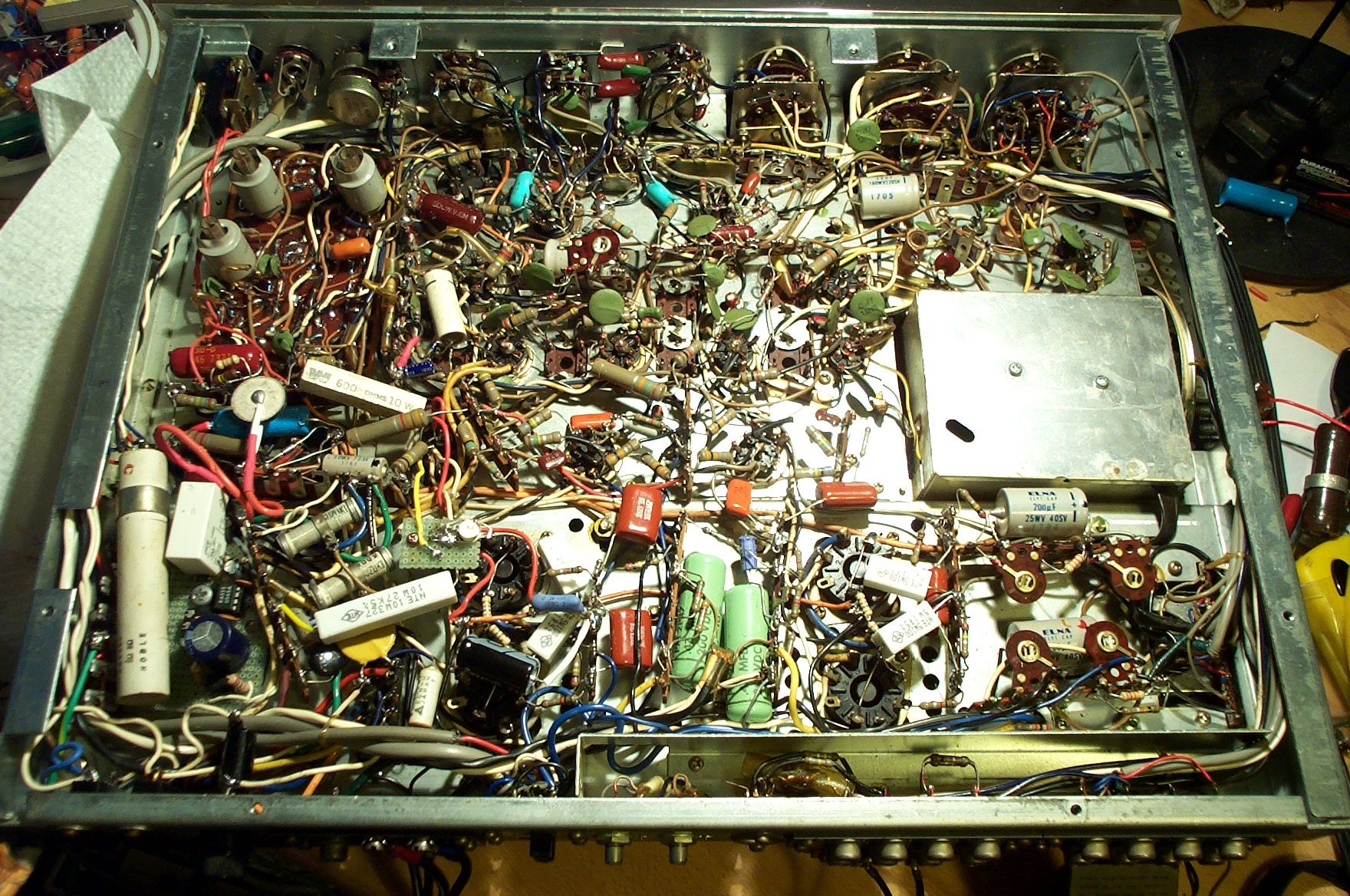

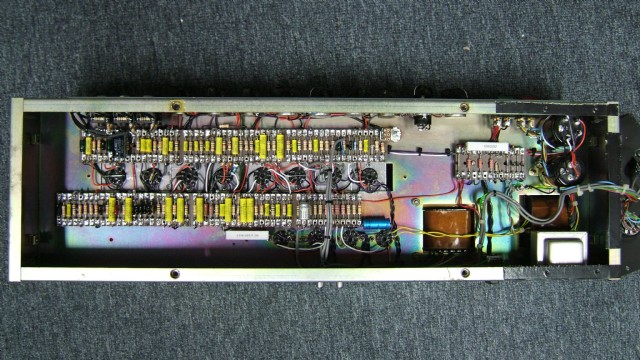

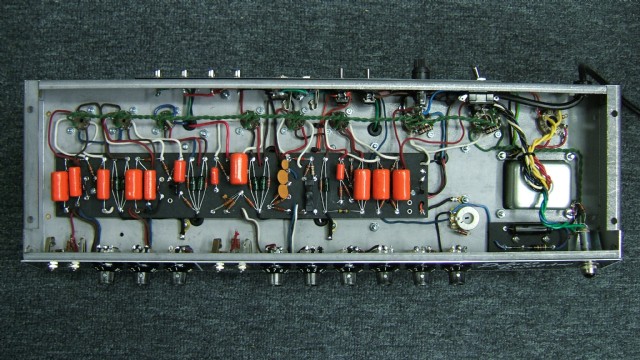

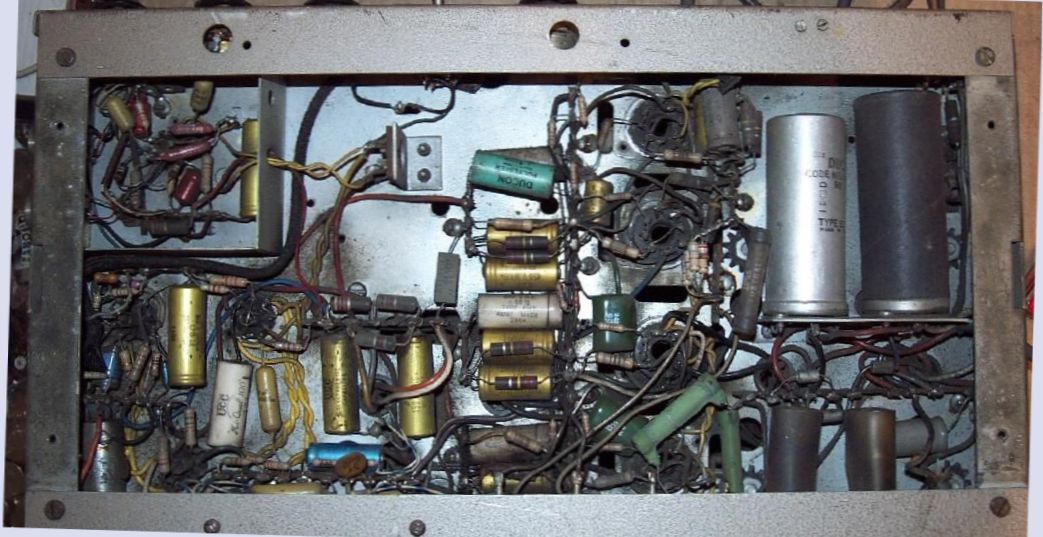

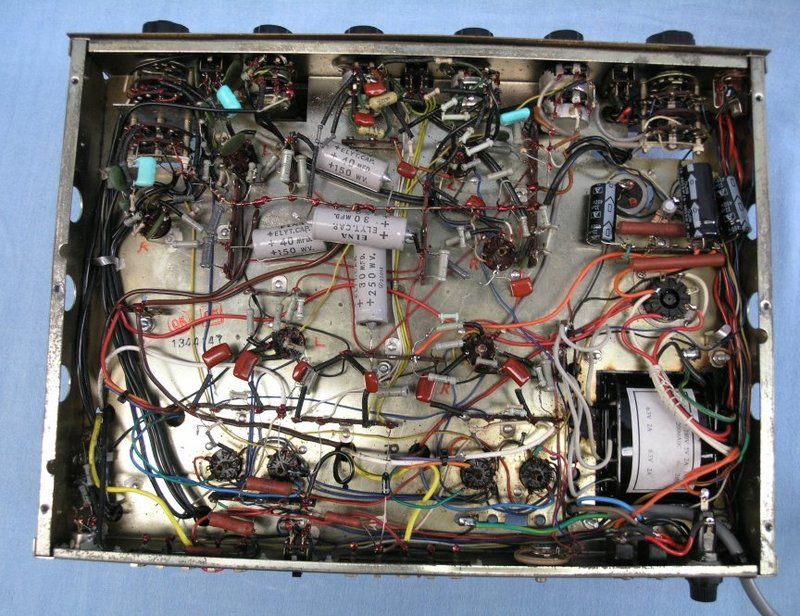

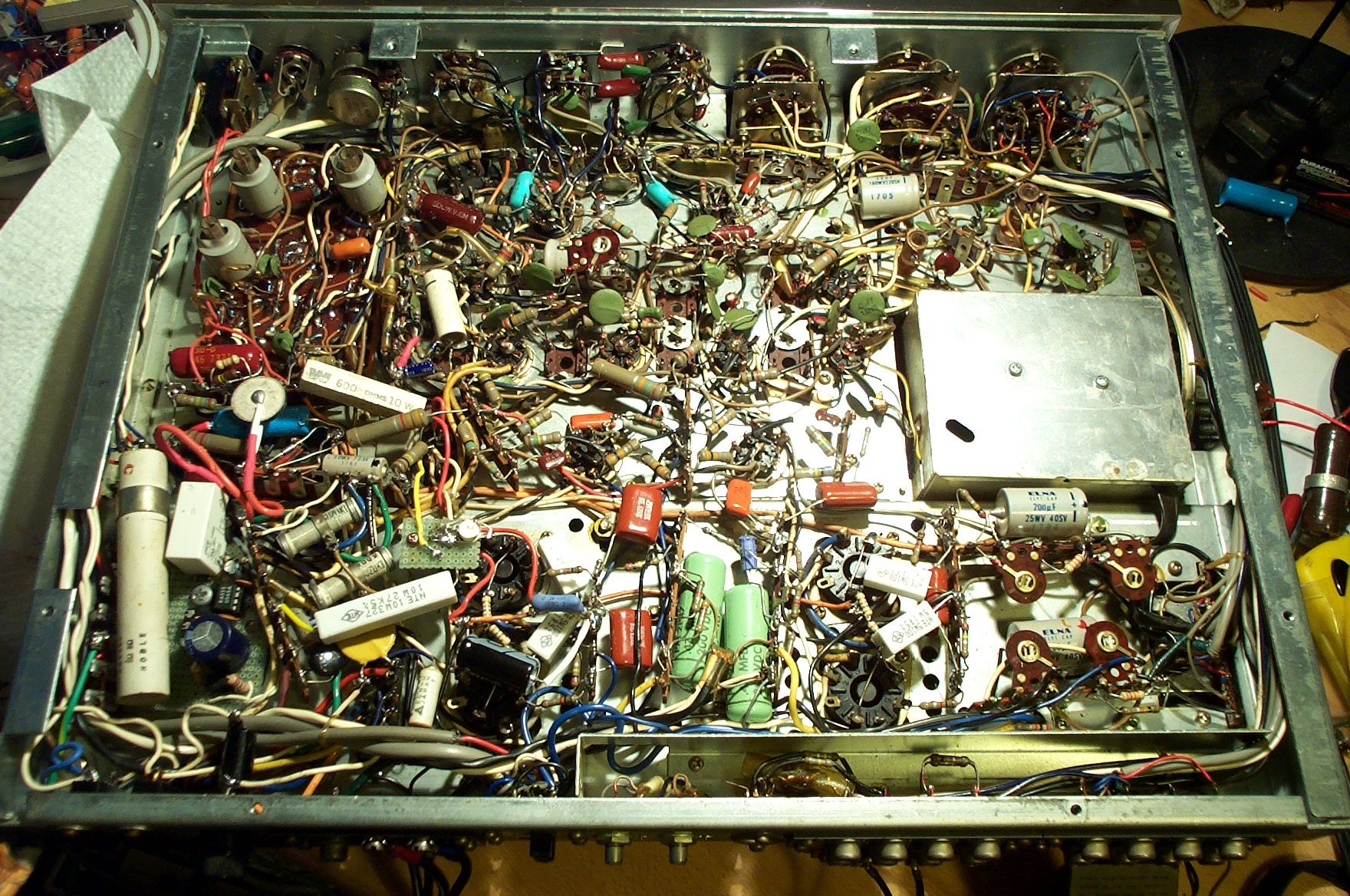

EXAMPLE 3: LAYOUTS TO AVOID

Note the psychedelic artform wiring and complex layouts.

Compare with the "CHASSIS AND

COMPONENT LAYOUT AND WIRING RULES" above

But they still work !!

Home

Page

This page is located at http://www.oestex.com/tubes/wiring.html

This page last modified 09 December 2015